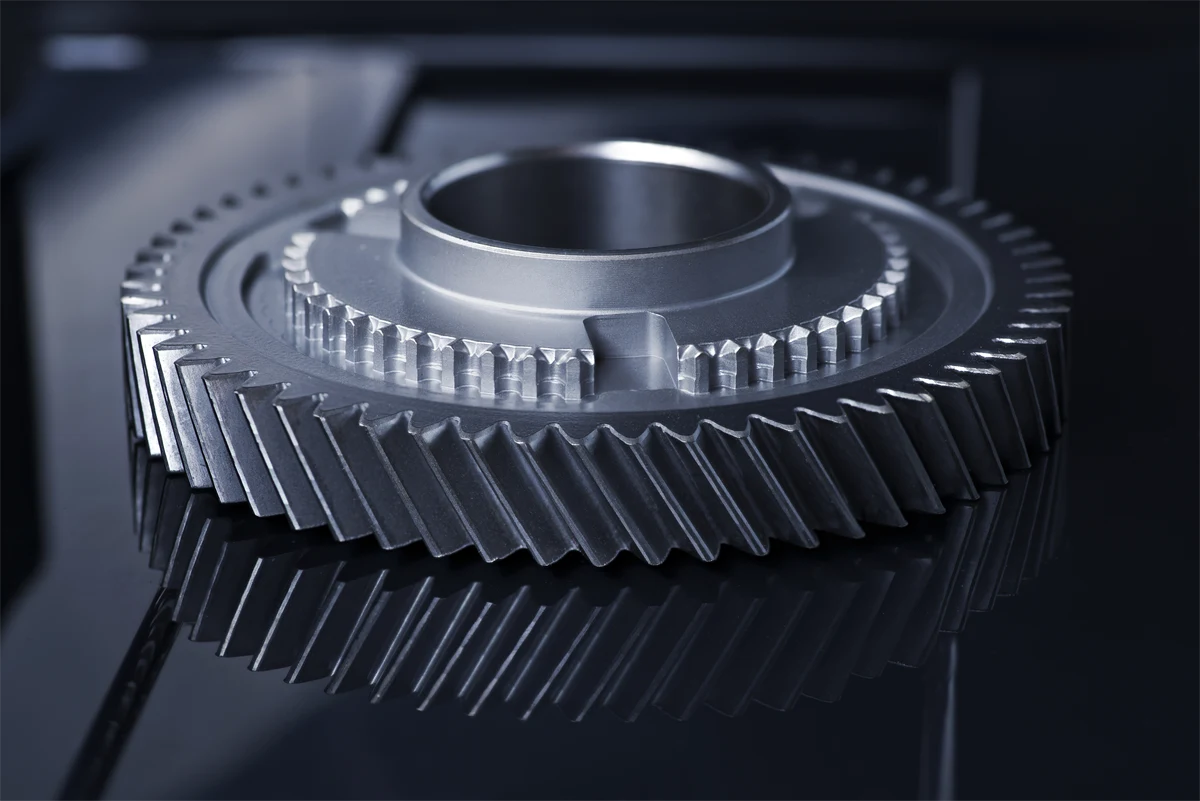

Sintered transmission gears

Recent developments in sintered gear technology have resulted in several technical benefits, providing OEMs with the opportunity to significantly shortening their in-house gear manufacturing process chain. Today, powder metallurgy (PM) is an attractive alternative for future gear-plant manufacturing strategies.

How transmission gears can benefit from PM

- Build-in functions

- Internal damping

- Downsizing synchroniser package

- Optimised gear root

- One-piece compactions

Design considerations when working with sintered gears

In order to improve design robustness, micro geometrical modifications must be calculated with the correct material data.

Make powder technology first choice

A key to successful product development and industrialisation is the intimate work with material, process and design. Höganäs can realise this by opening up for close collaborations in the Customer Development Centre.