Climate

Energy use

Surplus energy from our processes is converted into residual heat which we can deliver to external parties. In 2019, we delivered 51,000 (57,700) MWh in the form of surplus heat to district heating and municipal treatment plants in the Swedish cities of Höganäs and Halmstad. The export from Höganäs saved community emissions corresponding to an estimation of 11,000 tonnes of carbon dioxide, compared to the normal production of heat by natural gas incineration.

In 2019, we purchased 486,200 (527,100) MWh of electricity of which 50 (53) per cent was from renewable or partly renewable sources. We produced 190 (80) MWh of renewable electricity at our own facilities.

Energy management and efficiency

Our target is that the most energy intensive units within the Group, those with melting operations, should be ISO 50001 (energy management) certified by the end of 2021. It is part of our resolve to be even more energy efficient. Our major Swedish production sites are already certified, and other production sites are on their way towards compliance and will be certified during the years to come.

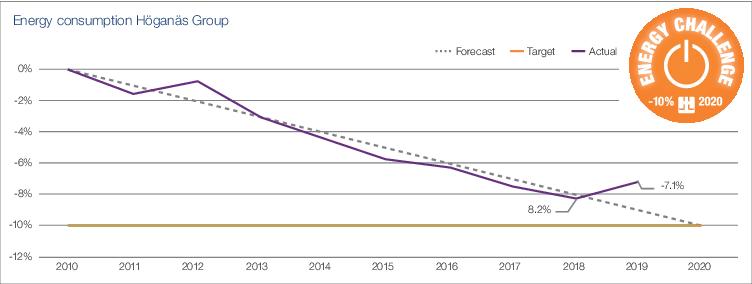

Our energy efficiency initiative, the “Energy Challenge”, has been successful, seeing a steady decline in energy use. The target is a 10 per cent reduction per produced tonne of metal powder between 2010 and 2020. The result for 2019 was a 7.1 (8.2) per cent decrease in energy use per produced tonne compared to 2010.

In 2019 further steps were taken to increase the total energy efficiency. One example is installation of variable-frequency drives that reduce power demand for electric motor-driven systems such as ventilation, fans, pumps and compressors.

In Sweden we commissioned a new state-of-the-art annealing furnace, thereby replacing older furnaces. The energy savings, primarily through the use of natural gas, result in an average reduction of 2,000 tonnes of carbon dioxide per year.

Also in Sweden, the electric arc furnace was fitted with oxy fuel burners that give the possibility for optimizing the scrap melting process for energy efficiency. Early results are promising.

| Energy use within the organization in MWh | 2019 | 2018 |

| Non-renewable fuels | 412,000 | 456,100 |

| Renewable fuels | 5,100 | 2,700 |

| Total energy use from fuels in MWh | 417,100 | 458,800 |

| Purchased electricity | 235,000 | 249,000 |

| Purchased electricity from renewable or partly renewable sources | 234,000 | 277,000 |

| Purchased heat, steam or cooling | 17,200 | 2,100 |

| Total purchased energy in MWh | 486,200 | 528,100 |

| Self generated energy from renewable sources** | 190 | 80 |

| Total energy use | 903,490 | 986,980 |

* Corrections made on reporting of Non-renewable fuels: 10 400 MWh added to the result for 2018

** Only energy from renewable sources. Energy generated from surplus process heat is excluded (produced and sold)

The Energy Challenge target has developed nicely over the years, but in 2019 we did not achieve the expected level. The reasons for that are two-fold:

1. Lower production output had a negative impact on the Group’s energy consumption per produced tonne, as Höganäs operates high temperature processes, where activities like cooling, heating and idling, as well as energy base load, do not go down in proportion to production volumes.

2. Our biggest energy-saving investments – the state-of-the-art annealing furnace and the installation of the oxy-fuel burners – were in operation late in the year thus not providing enough energy savings to compensate.

The production volumes during 2019 are comparable with

the volumes from the target base year of 2010. Interestingly, the result shows clearly that we are more than 7 per cent more energy efficient and that it is not an effect of volume.