Material use is one of our focus areas at Höganäs for several reasons beyond resource efficiency. What type of material we use, affects our carbon dioxide emissions, our environmental footprint from our production processes and the life-cycle footprint of our products.

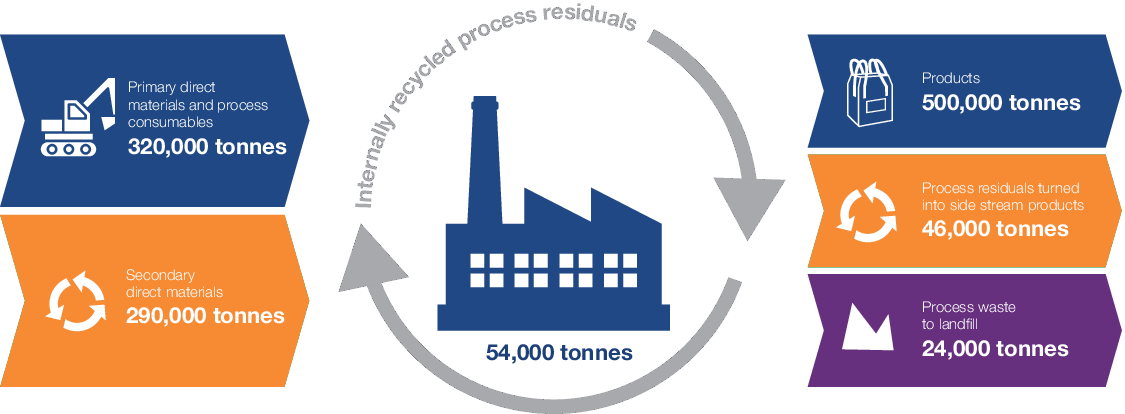

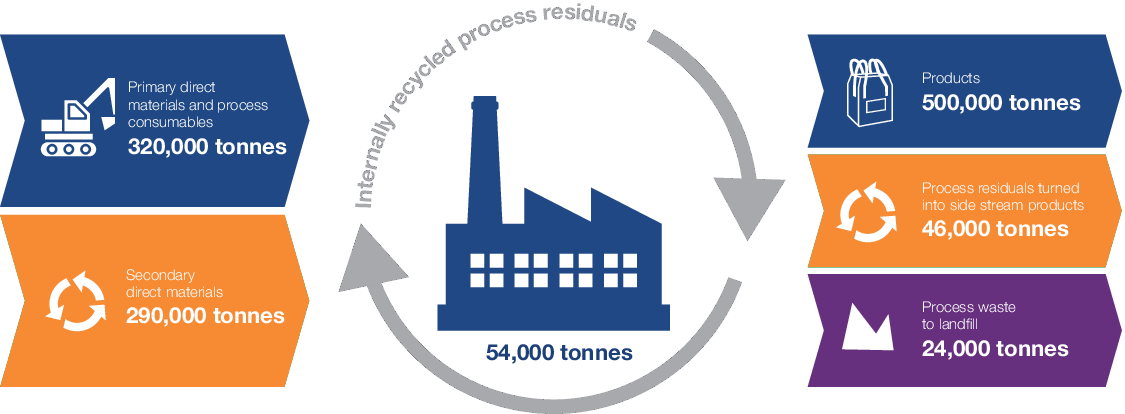

In 2019 we handled a total of 611,000 (719,000) tonnes of direct materials to produce around 500,000 tonnes of products and 46,000 (59,000) tonnes of side stream products. Our largest raw material volumes are non-renewable in the sense that they are extracted from the earth’s crust. These materials are mainly iron ore, limestone and fossil process coal or coke.

We also buy non-ferrous metals like copper, chrome, nickel, molybdenum, tungsten, manganese and cobalt. A significant part of non-ferrous metals are secondary materials.

Material flow and efficiency

Approximately 50 per cent of our raw materials base consists of secondary, or recycled materials. Secondary materials include both pre- and post-consumer scrap. Our largest secondary material type by weight is iron-based scrap, which amounted to more than 290,000 (350,000) purchased tonnes in 2019. Our ambition is to increase the percentage of secondary materials.

The packaging material amounted to 2,160 (2,340) tonnes, of which 6 (7) per cent was renewable material. In some cases, non-renewable materials, like plastics, can be a more sustainable alternative as it has a longer life-span and is fully recyclable.