Environment

Water use

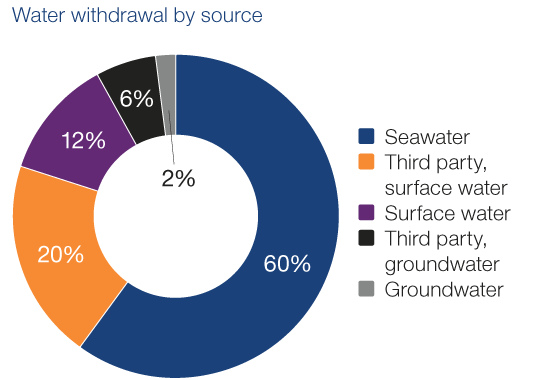

The largest quantity of water that we use is seawater for cooling in closed systems. In 2019 we used 4,140 (4,160) thousand cubic metres. In Sweden, much of the heat produced in these systems is used for district heating. Our use of seawater, even in large quantities, does not have significant environmental impact, as the same quantity is returned to the ocean in the same state as it was taken.

In Halmstad we use drinking water for cooling. In 2020 a project will investigate the possibility and technical solutions for using other water sources such as rivers or seawater in order to minimize the use of drinking water.

Water is also used in the atomizing process where molten steel is atomized into the desired particle sizes in a controlled ‘water jet’ process. The water is treated, cooled and largely recycled within the atomizing process. Water for dust binding and slag quenching is evaporated, treated on site or sent off to external water treatment plants.

Our production sites are generally located in areas where freshwater supply is still plentiful. The exception is our Indian site in Ahmednagar, where seasonal fluctuations cause water stress either in the form of flooding or drought. Measures are being taken to economize the use of water and store water for usage during dry periods.

Water intensity is1.4m3 per produced tonne |

| Water use, cubic meters | 2019 | 2018 |

| Total volume of water withdrawn | 6,866,000 | 6,260,000 |

| of which seawater | 4,140,000 | 4,160,000 |

| of which freshwater | 2,726,000 | 2,100,000 |

| Total water discharges | 6,232,000 | 5,587,000 |

| Total water consumption | 634,000 | 673,000 |