Society

Our responsibility towards society is also noticeable in our transparency and our compliance with legislation, including our financial and non-financial reporting, our tax payments and our attitude towards external parties dependent on our business.

Responsible sourcing

Responsible sourcing is very important to us, as a large part of our social impact takes place in our supply chain. We need to choose our suppliers with discernment, as they can either work together with us to improve our mutual sustainability performance, or otherwise they can pose a risk that will prevent us from achieving our goals.

Our supply chain is global which means that the geopolitical changes we see today affect material flows and costs. Sudden changes due to new tariffs, and the unintended consequences and volatility connected to them, create uncertainty and complicate purchasing. However, by closely monitoring market dynamics, diversifying the supply chain and being fast and flexible, these challenges can be turned into advantages.

More than half of our raw materials are sourced locally within the country of operation. Maintenance, consultancy and entrepreneur services are also sourced within the country of operation, with only a few exceptions.

In 2019 Höganäs Group counted 472 (535) suppliers of direct materials and approximately 6,500 suppliers of indirect materials, transportation and other services. Direct materials consist of raw materials, process consumables and packaging materials.

Compliance with internationally agreed principles concerning business ethics, anti-corruption, and respect for human rights and fair labour standards, as well as environmental precautions, is fundamental. Because of the type of raw material we purchase, we have some risks concerning artisanal mining and conflict minerals that we need to manage carefully. Ethical business behaviour that is rooted in common values builds mutual trust that enables smooth and uninterrupted supply.

Our objective is to communicate our Supplier Code of Conduct to all new suppliers, and to existing suppliers in conjunction with renewed agreements. In 2019 we on-boarded 14 (8) new suppliers of direct materials and 166 new suppliers of indirect materials and services. During 2019 we have communicated our Supplier Code of Conduct, which includes our anti-corruption policies, to 20 suppliers of direct materials and 416 suppliers of indirect materials and services. To date we have communicated our Supplier Code of Conduct to approximately 230 of our direct material suppliers, which is 49 (16) per cent.

Developing methods and tools

We are refining and developing our Responsible Sourcing programme, which consists of working methods for evaluation, selection and development of suppliers. The tools and principles in the programme address the challenges and risks that we have identified in our supply chain and help us to build strong relations with suppliers that we trust. Examples of identified risk areas are conflict minerals, rare earths, artisanal mining, palm oil, upstream GHG emissions and human rights infringements. With our current working methods and tools, we believe that we can both identify and mitigate risks in our supply chain.

Besides the requirement for new suppliers to fill out a standardized questionnaire covering their governance and performance within sustainability and quality related issues before on-boarding, we also evaluate several existing suppliers every year.

The objective is that all our suppliers of direct materials should be evaluated according to our Responsible Sourcing programme by 2021. We also put extra focus on evaluating suppliers of other goods or services that are critical to production. In 2019, 48 (50) suppliers were evaluated which makes 98 evaluated suppliers to date, or 20 per cent of our direct suppliers.

Incidents, non-compliances and identified increased risks concerning, for example, child labour, forced labour or freedom of association are reported through the group-wide reporting system. During 2019, no such cases were reported.

Four cases of insufficient responsiveness during 2019 called for in-depth dialogue with the supplier. After obtaining additional responses from each supplier, these cases could be closed without leading to further action. During 2019 there were 34 supplier audits including social criteria carried out and 8 audits including environmental criteria.

Value creation in the supply chain

We source raw materials globally and coordinate our purchases when this is practical and beneficial, from both a financial and environmental perspective. To minimize transportation, we prioritize local or regional suppliers and try to avoid transcontinental sourcing whenever possible. Our largest direct material spends are iron scrap, nickel and iron ore.

In 2019 we have identified possibilities for shifting from centralized purchasing to local when it comes to both metallic and non-metallic additives for our mixes. This could reduce transportation, improve cash flow and increase the value creation for the local market.

Most external services are purchased locally or within the country of operation. Höganäs is a large and stable business partner to many small and medium sized companies close to our operations around the globe.

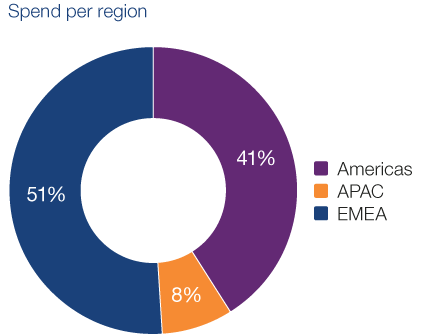

Our total spend on external suppliers in 2019 was 8,177 (7,753) MSEK of which 51 (52) per cent was spent in EMEA, 41 (41) per cent in the Americas and 8 (7) per cent in APAC. Approximately 15 per cent of our raw material in spend are sourced through distribution channels or traders.