A huge amount of industries are impacted because these semiconductors are critical parts of microchips, which are used in so many different applications. The number of applications is only increasing, too, with the smart device and electric car industries growing fast. In addition to this, people working from home and spending more time indoors due to the pandemic led to a rapid rise in demand for new computers, games consoles and graphics cards, all of which need these semiconductors.

Due to these shortages and production challenges, semiconductor manufacturers need to find ways to make their processes more efficient and reliable in order to increase output and ensure supply can meet demand. These manufacturers also need to find ways to increase overall capacity, which will often mean investing in entirely new production facilities. Additive manufacturing can help make these expansions and improvements have a greater positive impact.

Better tools in less time

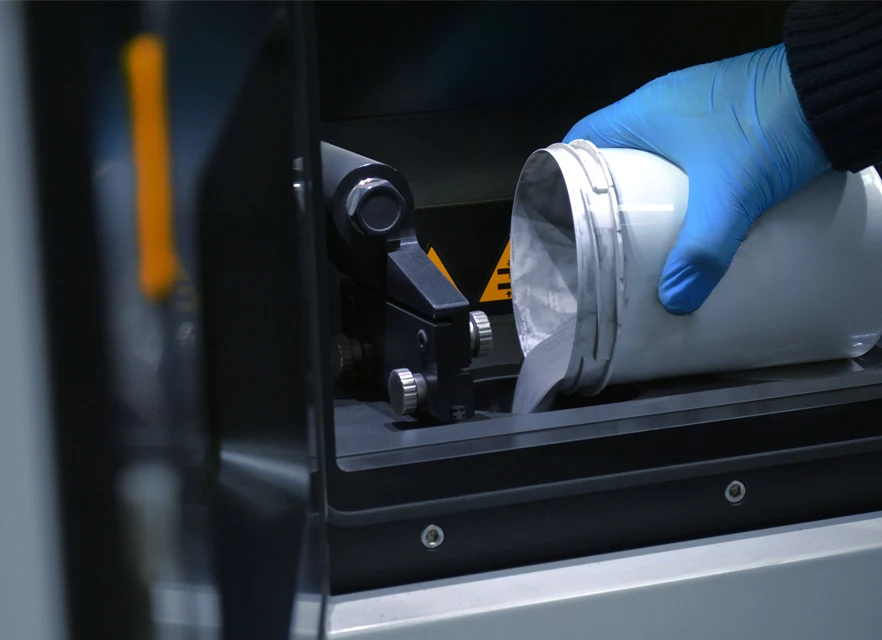

Manufacturing modern semiconductors requires state-of-the-art equipment which offers outstanding precision, accuracy and efficiency. The tools which allow this often need to be custom designed, and many of them can have lead times of more than half a year. However, with AM, the manufacture of these tools is simplified, the lead times are shortened, and even the most complex designs are possible.

The complexity of the designs matters because many challenges in semiconductor manufacture are related to thermal management. With more complex designs, it’s possible to fully optimize water flows and maximize the surface areas which can be cooled as necessary. One example of a more effective 3D printed component is a water table, which is part of the silicon-handling process in microchip manufacture. AM is facilitating next-generation designs which offer more effective thermal management, which allows for a more reliable and stable production process.

AM heat sink: IQ evolution / Elektronik Alvier Mechatronics. Learn more at www.connactive.tech

It’s also possible for manufacturers to reduce total part counts for some of the tools on the semiconductor production line, potentially reducing costs as well as improving efficiency. Single components are much easier to implement than tools that require assembly, which not only reduces the amount of time it takes to become operational, but it also simplifies servicing and maintenance.

Utilising AM to its fullest also allows designers to work according to their own specifications, rather than working within the limits of alternative methods. This means the tools can be the ideal fit for the specific production requirements without any compromises, allowing for a more efficient process.

All of these factors combined can help manufacturers to address this global shortage more quickly while improving their own production performance. AM is on the way to revolutionising a wide range of industries, and this is one case where the positive effects can be felt by people all over the world.

AM can also help to decentralise manufacturing processes, which in the case of semiconductors would be a great benefit. Rather than having to rely on a limited number of fabricators in remote locations, leveraging the flexibility of AM can help localise parts of the process and mitigate the risks associated with relying heavily on a small number of potential production partners.

Embracing AM is relatively straightforward for semiconductor manufacturers. There’s no need to invest in any 3D printing equipment, it’s just a case of finding the right partners and the right metal powder products. Together, it is then possible to make the tools and components necessary for a more productive, reliable and efficient manufacturing process.

Höganäs is a leading manufacturer of AM powders, and has a range of products designed specifically for efficient and productive 3D printing. Whatever your requirements, we have the ideal solution.

#InsightsByHoganas