Pós de fase sólida para plasma com arco transferido (PTA)

Pós Amperweld® para fase sólida

Amperweld CTC | C 4% | 150/53 µm

Particle size: 150/53 µm

Chemistry: C 4%

Powder type: -

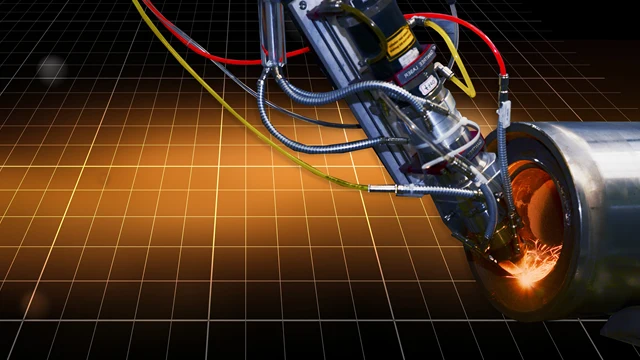

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld CTC | C 4% | 106/36 µm

Particle size: 106/36 µm

Chemistry: C 4%

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld SCTC | C 4% | 150/53 µm

Particle size: 150/53 µm

Chemistry: C 4%

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld MTC | C 4.3% – 5.2% | 150/53 µm

Particle size: 150/53 µm

Chemistry: C 4.3% – 5.2% (depending on particle size)

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld MTC | C 4.3% – 5.2% | 180/53 µm

Particle size: 180/53 µm

Chemistry: C 4.3% – 5.2% (depending on particle size)

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld VC | 160/63 µm

Particle size: 160/63 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld VC | 90/45 µm

Particle size: 90/45 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld VC | 45/5 µm

Particle size: 45/5 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld TiC | 200/106 to 45/5 µm

Particle size: 200/160 to 45/5 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld CrB | 400/63 µm

Particle size: 400/63 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Amperweld CrB2 | 400/63 µm

Particle size: 400/63 µm

Chemistry: -

Powder type: -

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Pós de fase sólida Surfit®

Misturas autofundentes + misturas de carbonetos Surfit® Ni

A Höganäs oferece uma ampla variedade de misturas de pós Surfit com ligas autofundentes de Ni (SF) e carbonetos de tungstênio.

Com um amplo portfólio de ligas autofundentes de Ni em combinação com diferentes carbonetos de tungstênio, nós misturamos sob medida para atender aos requisitos da aplicação.

- Ligas autofundentes de Ni

- Carbonetos de tungstênio Amperweld®

- Amperweld CTC - Carbonetos de tungstênio fundidos

- Amperweld SCTC - Carbonetos de tungstênio fundidos esféricos

- Amperweld MTC - Carbetos de tungstênio Macroline

- Amperit® Carbonetos de tungstênio e cobalto

- Amperit 519 WC-Co 88-12

- Amperit 526 WC-Co 83-17

Contate o seu representante de vendas local da Höganäs para encontrar uma solução adequada para a sua aplicação.

Tamanho da partícula: -

Química: -

Tipo de pó: Misturados

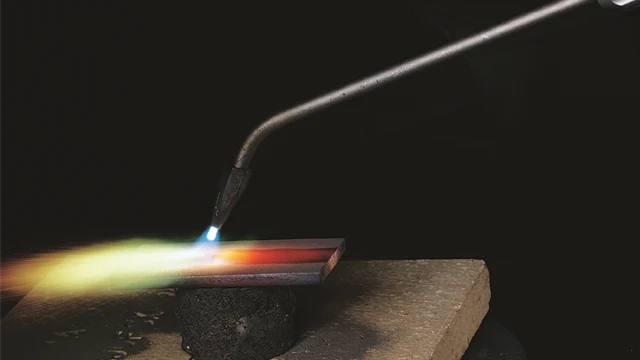

Técnicas típicas de deposição: Aspersão por chama, HVOF, revestimento a laser, plasma com arco transferido (PTA), soldagem a pó (maçarico por chama)

Fale conosco

Vendas e suporte

Política de privacidade

Concordo com o processamento de meus dados pessoais pela Höganäs para que possa contatar-me. Minhas informações de contato também podem ser usadas para fins de marketing, tais como envio de boletins informativos e outras informações relevantes. Os dados não serão compartilhados com terceiros. Juntamente com o meu consentimento, também confirmo que tenho mais de 16 anos.

Para saber mais sobre como processamos informações pessoais, consulte a nossa política de privacidade.