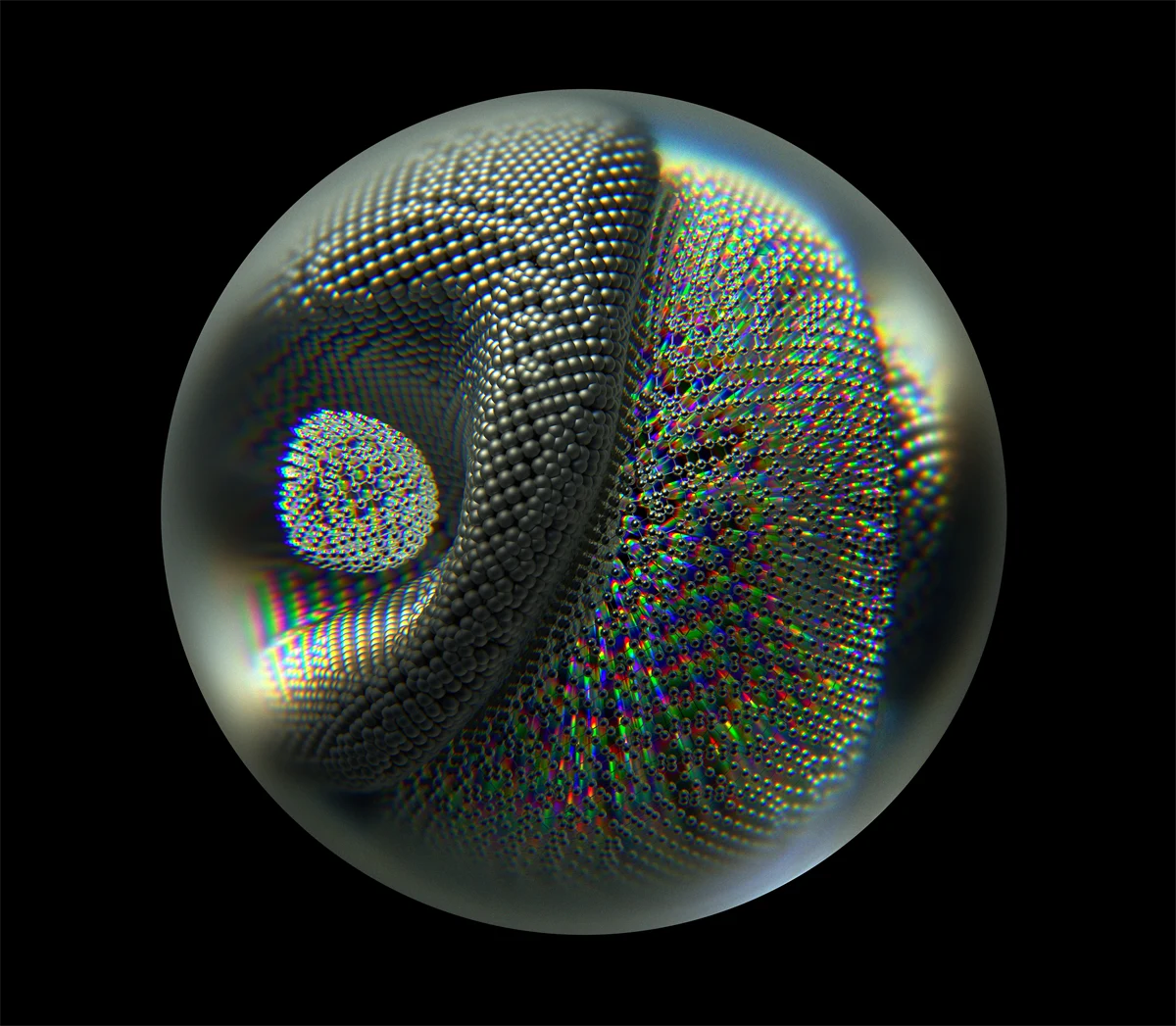

Fusão a laser em leito de pó, um processo adequado para a criação de peças com estruturas complexas

No processo a laser de fusão em leito de pó (LPBF) ou processo de fusão a laser seletivo (SLM), primeiro aplica-se uma fina camada de pó em uma plataforma de construção, geralmente de metal, com um recobridor que consiste em uma lâmina ou um rolo. Isso ocorre dentro de uma câmara compacta que contém gás inerte, argônio ou nitrogênio, com níveis de oxigênio extremamente baixos. Um feixe de laser funde seletivamente a camada de pó. Em seguida, a plataforma é abaixada gradualmente e uma nova camada de pó é aplicada. Depois disso, a operação de fusão por feixe de laser é repetida. Após um certo número de ciclos, contados em milhares, a peça é retirada do leito de pó.

Assim como com outros processos de manufatura aditiva, os componentes são construídos camada por camada com o processo de fusão a laser em leito de pó. Todo o processo começa com o recorte dos dados de um arquivo CAD 3D em uma imagem 2D das camadas.

A fusão a laser em leito de pó permite o desenho de geometrias orgânicas, estruturas complexas e paredes delgadas complicadas, que do contrário não seriam possíveis de ser fundidas ou usinadas. Os materiais que podem ser usados para a fusão a laser em leito de pó incluem ligas à base de níquel, cobalto cromo, aços inoxidáveis, aços ferramenta, aços para construção, titânio, cobre e alumínio.

O portfólio de pós para manufatura aditiva da Höganäs abrange produtos desenvolvidos especificamente para fusão a laser em leito de pó.

Fale conosco

Vendas e suporte técnico

Política de privacidade

Concordo com o processamento de meus dados pessoais pela Höganäs para que possa contatar-me. Minhas informações de contato também podem ser usadas para fins de marketing, tais como envio de boletins informativos e outras informações relevantes. Os dados não serão compartilhados com terceiros. Juntamente com o meu consentimento, também confirmo que tenho mais de 16 anos.

Para saber mais sobre como processamos informações pessoais, consulte a nossa política de privacidade.