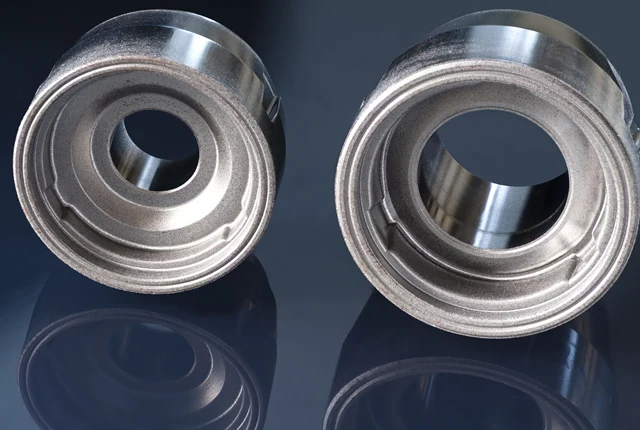

Cost-effective metal components are compacted and sintered

Sintered metal components are cost-effective metal components

Sintered components are cost-effective as they are manufactured in large series with high productivity and low energy consumption. Simply put, it is cheap to press and sinter large series in one and the same tool, because the press and sintering furnace have high productivity and low energy consumption and cost.

Cost-effective metal components are obtained when material utilisation in the production process is close to 100 percent, and when the manufacturing process has high productivity and is efficient, which is the case for pressing and sintering. There is no need to process it in several steps such as with machining, casting or forging methods where a lot of material needs to be removed to obtain the final shape of the part. These steps add unnecessary costs and leaves residual scrap, which is not environmentally friendly.

Saving operation costs

A shorter production process chain also leads to cost-effective metal components. With fewer operations per part, it reduces the number of machines and working stations needed, which in turn means lower investment and maintenance costs as well as reduced need for large production facilities.

Another important factor for achieving cost-effective metal components is to ensure the part can be designed in one piece despite a complex design.

All of these benefits above are obtained when using the compaction and sintering method when in need for cost-effective metal components.

Política de privacidade

Concordo com o processamento de meus dados pessoais pela Höganäs para que possa contatar-me. Minhas informações de contato também podem ser usadas para fins de marketing, tais como envio de boletins informativos e outras informações relevantes. Os dados não serão compartilhados com terceiros. Juntamente com o meu consentimento, também confirmo que tenho mais de 16 anos.

Para saber mais sobre como processamos informações pessoais, consulte a nossa política de privacidade.

Welcome to Höganäs Academy

Join Höganäs Academy and learn more about the capabilities and opportunities for pressed and sintered metal components.

In our online courses at Höganäs Academy, you get access to everything from an easy-to-read overview of what sintered components are and how they are produced to profound process know-how on how to optimise production efficiency and quality.