Manufatura Aditiva

– características

Como a VIGA é usada para obter pós metálicos para impressão 3D de alta qualidade

Atomização por gás inerte com fusão por indução a vácuo (VIGA)

A atomização por gás inerte com fusão por indução a vácuo ou VIGA é um dos principais processos de fabricação de grandes volumes de pós metálicos esféricos e de alta qualidade. Os nossos pós metálicos forAM® à base de cobalto, níquel e ferro são produzidos com o sistema VIGA específico e foram especificamente desenvolvidos para os requisitos da manufatura aditiva.

A VIGA é um método de produção flexível de última geração, caracterizado pela confiabilidade do processo, boa produtividade e baixo custo operacional. Graças ao sistema VIGA, podemos produzir consistentemente pós de alta qualidade com baixo teor de oxigênio e concentração baixa ou ajustada de nitrogênio, partículas esféricas e quantidade muito baixa de satélites, graças ao sistema anti-satélite integrado. Além disso, os pós para manufatura aditiva são de alta pureza, têm boas características de fluxo e distribuições granulométricas definidas (PSDs).

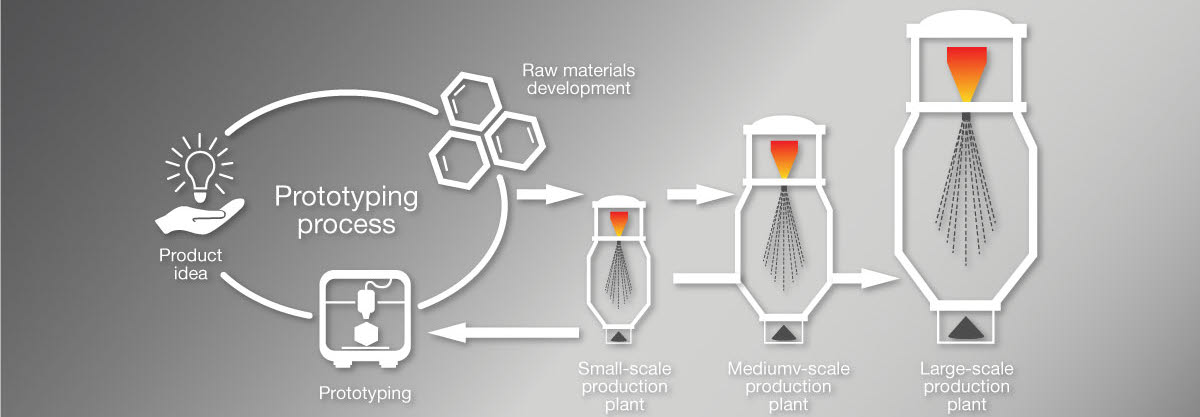

Por meio do nosso processo de atomização por gás inerte com fusão por indução a vácuo, podemos produzir qualquer quantidade de pós metálicos 3D sob medida, em escala laboratorial ou industrial, para suportá-lo nas várias etapas de desenvolvimento do seu produto.

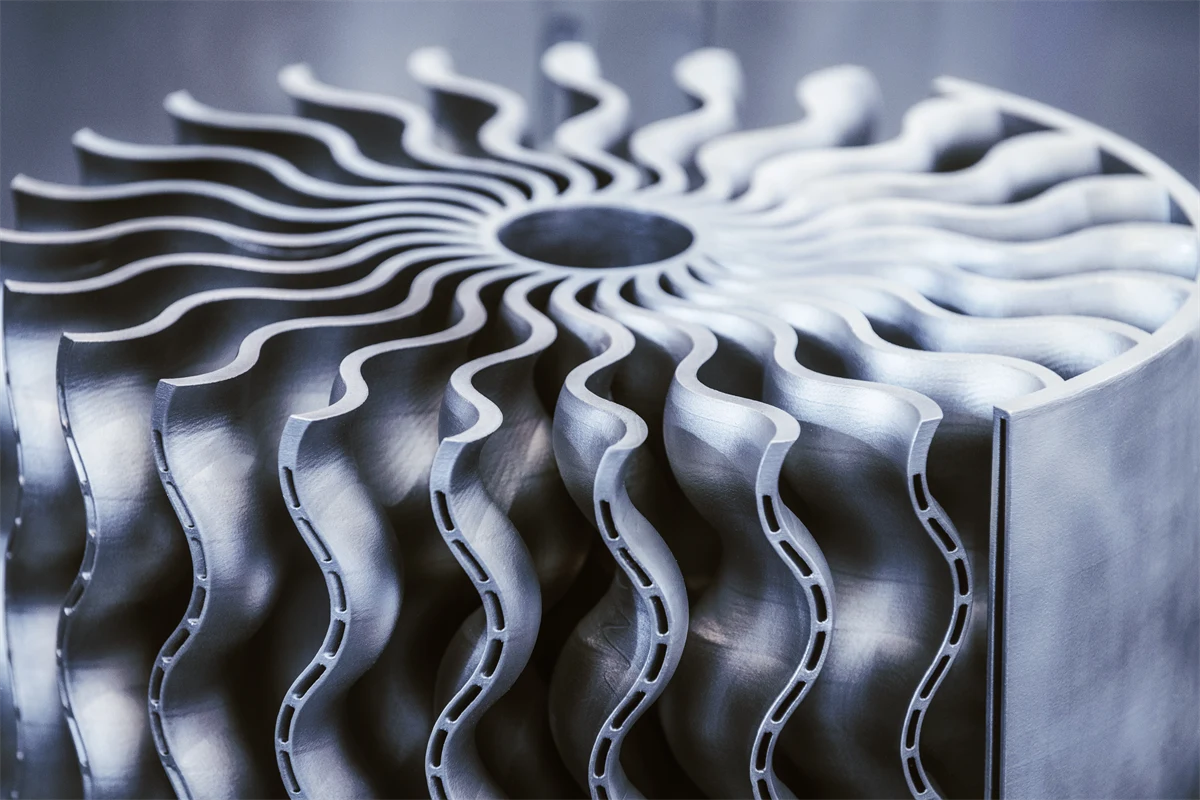

As principais aplicações dos pós para manufatura aditiva produzidos com a tecnologia VIGA podem ser encontradas nos setores Aeroespacial e Médico, bem como em turbinas industriais a gás (IGT). A VIGA é ideal para a produção de superligas de níquel, pós de cobalto-cromo, aços-ferramenta e aços inoxidáveis.

O sistema VIGA, combinado com nossos profundos conhecimentos metalúrgicos, significa que podemos oferecer a você o pó metálico para impressão 3D ideal para suas aplicações específicas.

Política de privacidade

Concordo com o processamento de meus dados pessoais pela Höganäs para que possa contatar-me. Minhas informações de contato também podem ser usadas para fins de marketing, tais como envio de boletins informativos e outras informações relevantes. Os dados não serão compartilhados com terceiros. Juntamente com o meu consentimento, também confirmo que tenho mais de 16 anos.

Para saber mais sobre como processamos informações pessoais, consulte a nossa política de privacidade.