增材制造

– 特性

如何使用VIGA获得高品质的金属3D打印粉末

采用真空感应熔炼惰性气体雾化技术,Höganäs可以以您选择的体积生产高纯度3D打印金属粉末。 VIGA用于生产高质量的钴基、镍基和铁基金属粉末。

真空感应熔炼惰性气体雾化(VIGA)

真空感应熔炼惰性气体雾化(VIGA)是用于生产大量球形高级金属粉末的主要粉末生产工艺之一。 我们高品质的钴基、镍基和铁基forAM®金属粉末均采用专用VIGA系统生产,并且专门针对增材制造的要求而设计。

VIGA是一种灵活的先进生产方法,具有流程可靠性、生产率高、运行成本低等特点。 使用VIGA系统时,由于集成的反卫星系统,我们可以生产始终高品质的粉末,这些粉末具有低氧、低或可调节的氮浓度、球形颗粒和极低的卫星颗粒。 此外,增材制造粉末的纯度高,具有良好的流动特性和明确的粒度分布(PSD)。

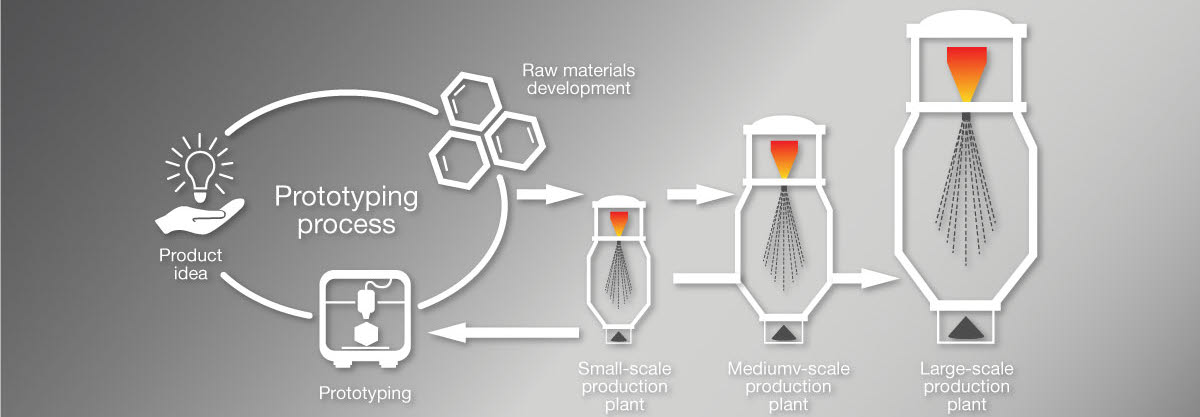

在我们的真空感应熔炼惰性气体雾化工艺中,我们可以生产从实验室规模到中等规模或工业生产规模等任何数量的定制3D金属粉末,以便在产品开发的各个阶段为您提供支持。

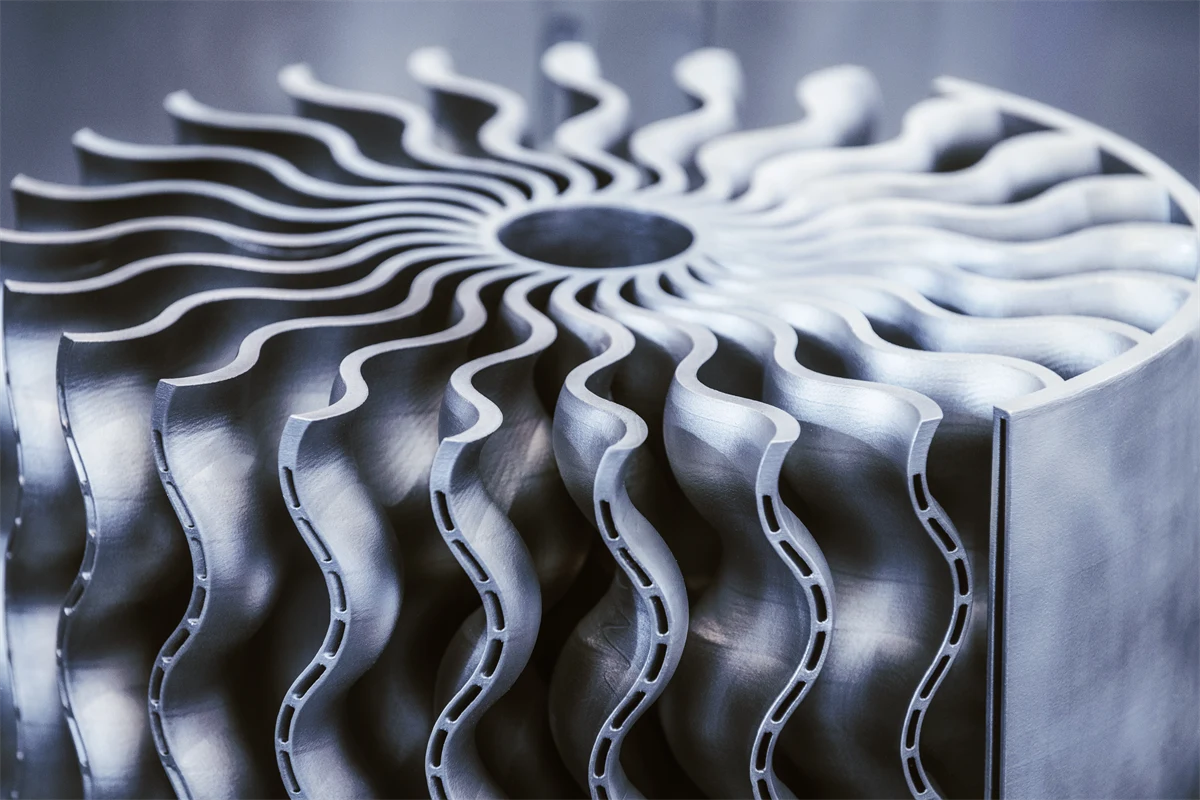

使用VIGA技术生产的增材制造粉末主要应用于航空航天和医疗行业以及工业燃气轮机(IGT)。 VIGA适用于生产超级镍合金、钴铬粉末、工具钢和不锈钢。

VIGA系统加上我们深厚的冶金技术,意味着我们可以为您提供适合您特定应用的3D打印金属粉末。

联系表

联系人

Technical area:

增材制造

选择国家/地区 *

联系方式 *

销售

销售

技术支持

名 *

姓 *

公司 *

工作领域 *

首席执行官/公司所有者

采购

设计工程师

业务开发人员

操作人员

其他

电子邮件 *

工作电话 *

留言 *

隐私政策

我同意Höganäs以联系我为目的处理我的个人数据。 我的联系信息也可能用于营销,如业务通讯和其他相关信息。 数据不会与第三方进行共享。 本人已同意,并且确认已年满16周岁。

更多关于我们如何处理个人数据的信息,请参阅我们的隐私政策。

您必须先接受这些服务条款才能继续。