BrazeLet® 阻焊产品

——–使钎焊应用更加完善

阻止熔融态钎料流动的阻焊解决方案

当您想防止熔化的钎料流入不希望或不需要有钎料的区域,BrazeLet® Stop-off 是一款有效的产品。 BrazeLet Stop-off 产品系列包含三种不同产品,可作为普通阻焊剂使用,如果希望表面光洁,也可使用优化产品,钎焊后更易于清除。

这些阻焊解决方案由通用即用型水性悬浮剂组成,可阻止熔化的钎料流动, 可以很好地配合Höganäs的所有钎焊填充料用于高温钎焊。 除钛、锆及其合金等活性金属外,这些阻焊产品可用于任何铁基或非铁基材料, 它们可用于真空钎焊,也可用于控制气氛钎焊。

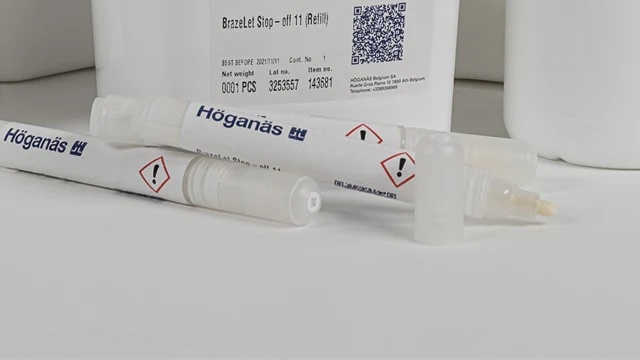

Höganäs共提供三种阻焊产品。 推荐BrazeLet Stop-off 10用于通用钎焊,尤其适合用在夹具上。 可通过刷涂、滴涂或喷涂的方式涂抹。 BrazeLet Stop-off 11与BrazeLet Stop-off 10的性能相同,但专门为与标记笔配合使用而设计。 更多关于BrazeLet Stop-off 11阻焊笔的更多信息,请点击此处。 如果需要在钎焊后表面光洁度达到最佳,建议使用BrazeLet Stop-off 20。 这种阻焊产品在钎焊后特别容易清除。

这三种阻焊产品均无气味,完全是水基的。 Höganäs 的阻焊笔可重复填充,从而能够降低成本,持续使用。

BrazeLet® 阻焊产品

BrazeLet Stop-off 10

BrazeLet Stop-off 11

BrazeLet 11 专门为与标记笔配合使用而开发。 更多关于 BrazeLet Stop-off 11 阻焊笔的信息,请点击此处。

Höganäs 的 阻焊笔 可重复填充,从而能够降低成本,持续使用。

BrazeLet Stop-off 20

联系我们

销售与技术支持

有关更多信息和要求,请联系您的销售代表。

联系我们

联系表

联系人

Technical area:

Brazing

选择国家/地区 *

联系方式 *

销售

销售

技术支持

名 *

姓 *

公司 *

工作领域 *

首席执行官/公司所有者

采购

设计工程师

业务开发人员

操作人员

其他

电子邮件 *

工作电话 *

留言 *

隐私政策

我同意Höganäs以联系我为目的处理我的个人数据。 我的联系信息也可能用于营销,如业务通讯和其他相关信息。 数据不会与第三方进行共享。 本人已同意,并且确认已年满16周岁。

更多关于我们如何处理个人数据的信息,请参阅我们的隐私政策。

您必须先接受这些服务条款才能继续。