BrazeLet® Stop-off products

– to perfect your brazing applications

A stop-off brazing solution that prevents flow of molten brazing filler metals

These stop-off brazing solutions act as a barrier to the flow of molten brazing filler metal and consist of ready-to-use water-based suspensions designed for general use. They work very well in high-temperature brazing together with any of Höganäs’ brazing filler metals. The stop-offs can be used on any ferrous or non-ferrous base material, except for reactive metals such as titanium and zirconium and their alloys. They work in both vacuum and controlled atmosphere brazing.

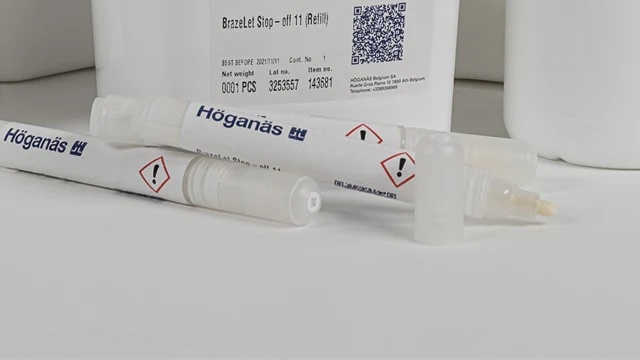

Three stop-off brazing products are available. BrazeLet Stop-off 10 is recommended for general brazing applications, and especially for application on fixtures. It can be applied by brushing, dispensing or spraying. BrazeLet Stop-off 11 has the same properties as BrazeLet Stop-off 10, but is specifically designed for application with a marker pen. You can read more about BrazeLet Stop-off 11 pen here. BrazeLet Stop-off 20 is recommended when the best surface finish after brazing is needed. This stop-off brazing product is particularly easy to remove after brazing.

All three BrazeLet Stop-offs are odourless and completely water-based. Höganäs’ stop-off brazing pen is refillable, which decreases your costs and offers a more sustainable use.

BrazeLet® Stop-off products

BrazeLet Stop-off 10

BrazeLet Stop-off 11

BrazeLet 11 is specifically designed for application with a marker pen. You can read more about BrazeLet Stop-off 11 pen here.

Höganäs’ stop-off brazing pen is refillable, which decreases your costs and offers a more sustainable use.

BrazeLet Stop-off 20

Contact us

Sales & Technical support

Personuppgiftspolicy

Jag godkänner att Höganäs hanterar mina personuppgifter för att kontakta mig. Min kontaktinformation kan även komma att användas för marknadsföringsändamål, som nyhetsbrev och annan relevant information. Uppgifterna kommer inte att delas med någon tredje part. I och med detta samtycke bekräftar jag även att jag är över 16 år.

Mer information om hur vi hanterar personuppgifter anges i vår personuppgiftspolicy.