Effective powder management

– for AM powder handling

Move your AM production into industrial scale with this powder handling system

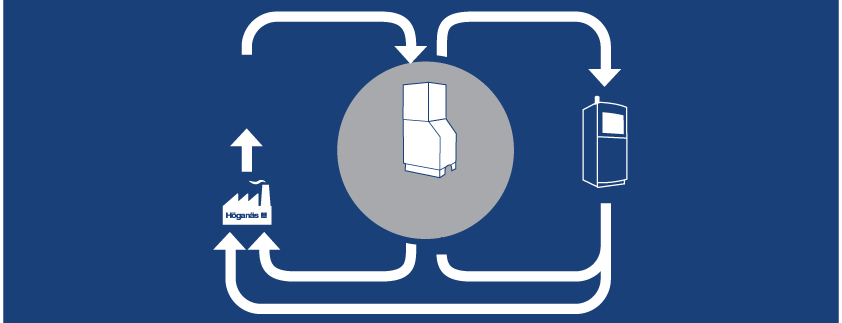

The AM powder handling concept includes a new type of package, specially developed for protecting additive manufacturing powders. The flexbag comes in two sizes, 200 and 500 kg, and is loaded onto a discharging unit, which can be connected to any type of hopper used in production. Once connected to the powerful discharging unit, the powder handling system allows completely dust-free discharge of powder. It is completely tight and proven with deliveries of very sensitive material overseas.

This concept makes industrialisation of additive manufacturing production possible. In addition, the powder management solution is easily adapted for any scale and AM system.

The new AM powder handling system allows for efficient shipping of powder, including possibilities to monitor the position and transport environment, vendor-managed inventory and minimised waste of both bulky packaging material and transport of dead volume and weight.

Höganäs develops metal powders for all major additive manufacturing processes, such as laser metal deposition, selective laser melting, electron beam melting and cold spraying.

Höganäs offers a broad portfolio of metal 3D printing powders, from consistent and cost-effective volume products to customised powders using the most advanced technologies available, including vacuum induction melting inert gas atomisation (VIGA).

Personuppgiftspolicy

Jag godkänner att Höganäs hanterar mina personuppgifter för att kontakta mig. Min kontaktinformation kan även komma att användas för marknadsföringsändamål, som nyhetsbrev och annan relevant information. Uppgifterna kommer inte att delas med någon tredje part. I och med detta samtycke bekräftar jag även att jag är över 16 år.

Mer information om hur vi hanterar personuppgifter anges i vår personuppgiftspolicy.