Pressing & Sintering

The gate for innovations

Why choose sintered parts?

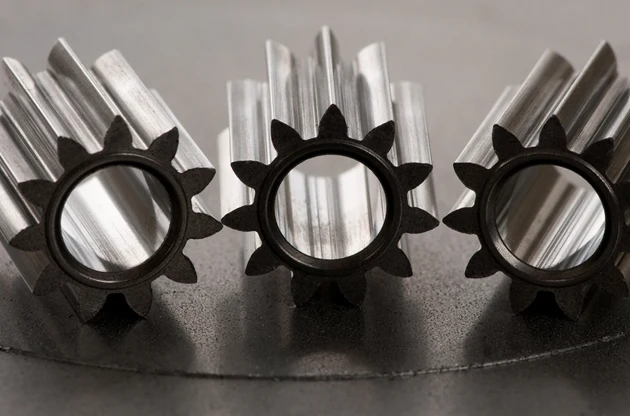

Sintered parts open up new possibilities for creative and cost-effective design solutions. Producing structural parts from powder has proven to be more competitive vs. other production technologies for a big variety of applications, especially for complex part geometries.

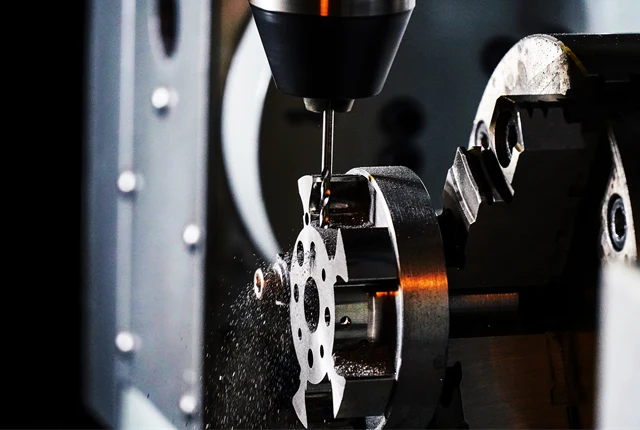

The manufacturing process involves the compaction of a powder mid and subsequent sintering. Over 40 million sintered components are produced every day for use in numerous applications.

With sintered metal parts, less is more. Less process steps, less machining and less wastage of material and energy in production add up to a solution with lowest total cost.

Sintered parts can offer far more than cost savings. They can be made from tailored materials serving specific purposes and with a design that would be impractical or impossible for other manufacturing technologies.

Höganäs wide selection of iron-based powders ensures the right solution for each part and process.

Making powder technology first choice

A key to successful product development and industrialisation is the intimate work with material, process and design. Höganäs can realise this by opening up for close collaborations in the Customer Development Centre.

The Customer Development Centre provides a platform for cross-functional work of different companies and competencies to work in all parts of the value chain from a desktop idea to a finished product.

The materials expertise to select the right powder solution.

The design support to create innovative PM applications.

The process know-how to ensure optimum production efficiency and quality.

Applications

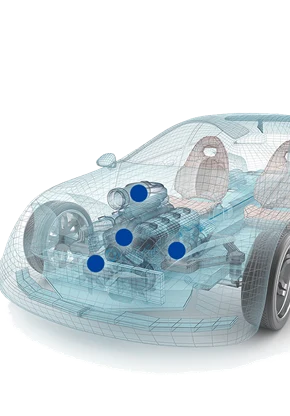

The automotive industry is the main use of sintered components, which are common in systems for transmission, engine, chassis and exhaust.

The use of sintered components is gradually increasing outside the automotive sector too,

but there is still a huge potential to be released. Parts produced form powder serve special funtions i power tools, white goods, appliances, air-conditioners, computers, lawn movers, locks and pumps.

"These are just a few exampels and the posibilities are endless."

Tune up for top preformance

There are two fundamental ways to improve profit: reducing costs and increasing sales. We believe we can do both. Höganäs high precision Fe-Cu-C toolbox for improved operational excellence.

Inspire industry to make more with less

Höganäs is the global leader in innovating new PM materials and applications and driving the market for PM solutions. Our goal is to expand the market for metal powder technology by finding new applications through improved performance and technological advancement. We do that through close cooperation and partnerships, thorough understanding of application needs and design aspects, and by adding process development and powder material innovations to the equation.

Contact us

Sales & Technical support

Personuppgiftspolicy

Jag godkänner att Höganäs hanterar mina personuppgifter för att kontakta mig. Min kontaktinformation kan även komma att användas för marknadsföringsändamål, som nyhetsbrev och annan relevant information. Uppgifterna kommer inte att delas med någon tredje part. I och med detta samtycke bekräftar jag även att jag är över 16 år.

Mer information om hur vi hanterar personuppgifter anges i vår personuppgiftspolicy.