Deposition techniques

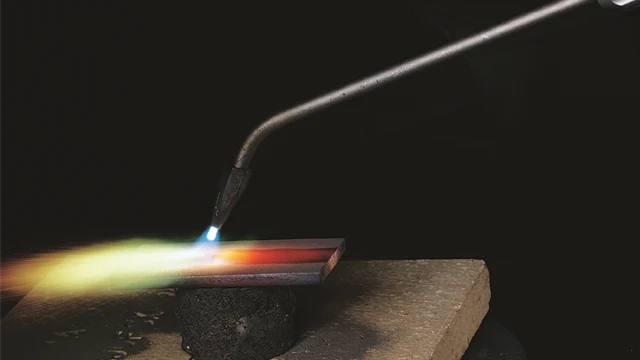

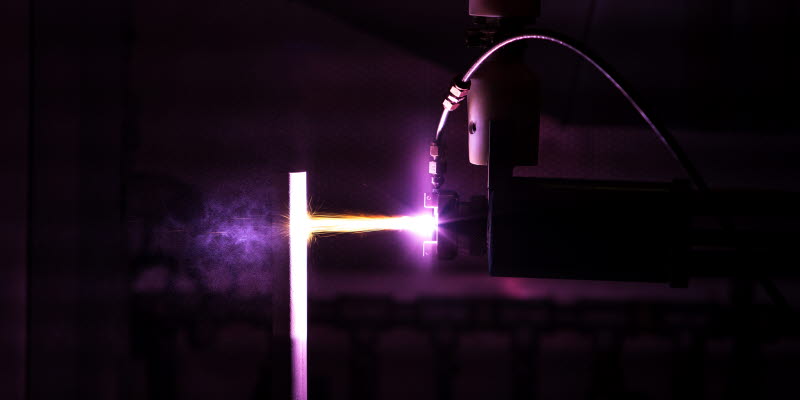

What is atmospheric plasma spraying?

In the atmospheric plasma spraying (APS) process, metals or alloys are melted and sprayed onto a surface using a plasma jet heated to more than 10,000 °C.

Atmospheric plasma spraying can be used with a wide range of materials and creates a high-quality and repeatable coating. It is often used to protect against wear, corrosion, oxidation, for thermal insulation or to improve a substrate’s function.

Atmospheric plasma spraying employs a technique essentially similar to PTA welding. The difference is that the flame comprises an electrically excited plasma of high velocity and temperature (≈15,000°K). This permits a denser coating (95-98%). Deposition rates range from 2 to 8 kg/hour, and surfacing thickness from 0.1 to 2.5 mm.

Personuppgiftspolicy

Jag godkänner att Höganäs hanterar mina personuppgifter för att kontakta mig. Min kontaktinformation kan även komma att användas för marknadsföringsändamål, som nyhetsbrev och annan relevant information. Uppgifterna kommer inte att delas med någon tredje part. I och med detta samtycke bekräftar jag även att jag är över 16 år.

Mer information om hur vi hanterar personuppgifter anges i vår personuppgiftspolicy.

ArcX coating hub

ArcX – Your starting point for innovation

Expert know-how in materials, surface welding and flame spraying processes and customer applications make our ArcX technology centres an exclusive resource in your work to optimise existing applications and develop new business opportunities.