Deposition techniques

Vacuum plasma spray/low pressure plasma spray (VPS/LPPS)

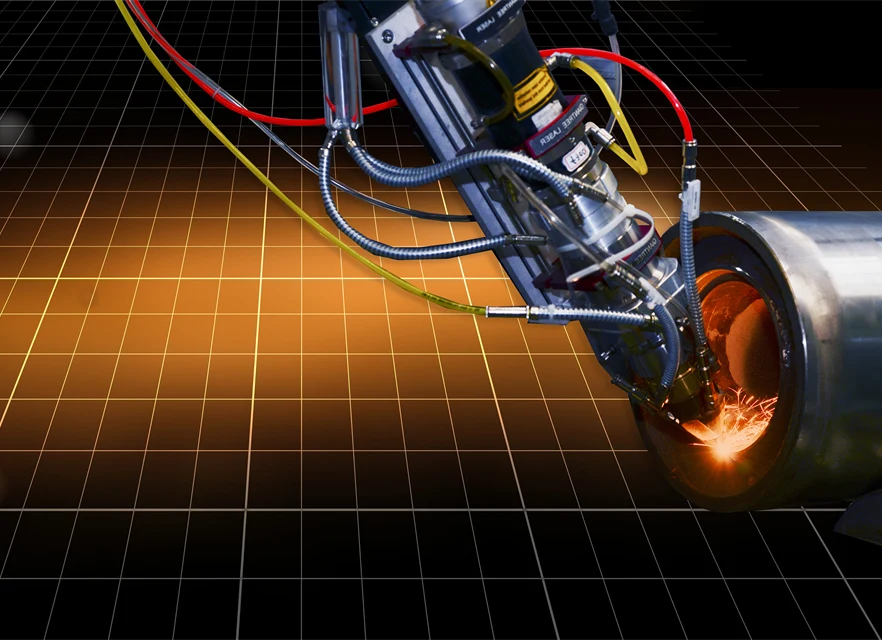

Just like atmospheric plasma spraying, vacuum plasma spraying (VPS) or low-pressure plasma spraying (LPPS) is a thermal spraying technology. It is carried out inside a vacuum chamber or in an inert gas, such as argon, maintained at low pressure to avoid oxidation. Metal or ceramic powders are injected into a hot gas plasma, which melts the powders. The molten droplets are projected onto a substrate to form the coating.

The advantage with VPS/LPPS is that the spraying speed and temperature of molten particles can be higher than in air, resulting in coatings with reduced oxide inclusions, higher bonding strength and density than what can be achieved by APS. VPS/LPPS coatings have low porosity and high purity.

Personuppgiftspolicy

Jag godkänner att Höganäs hanterar mina personuppgifter för att kontakta mig. Min kontaktinformation kan även komma att användas för marknadsföringsändamål, som nyhetsbrev och annan relevant information. Uppgifterna kommer inte att delas med någon tredje part. I och med detta samtycke bekräftar jag även att jag är över 16 år.

Mer information om hur vi hanterar personuppgifter anges i vår personuppgiftspolicy.

ArcX coating hub

ArcX – Your starting point for innovation

Expert know-how in materials, surface welding and flame spraying processes and customer applications make our ArcX technology centres an exclusive resource in your work to optimise existing applications and develop new business opportunities.