Services

– brazing

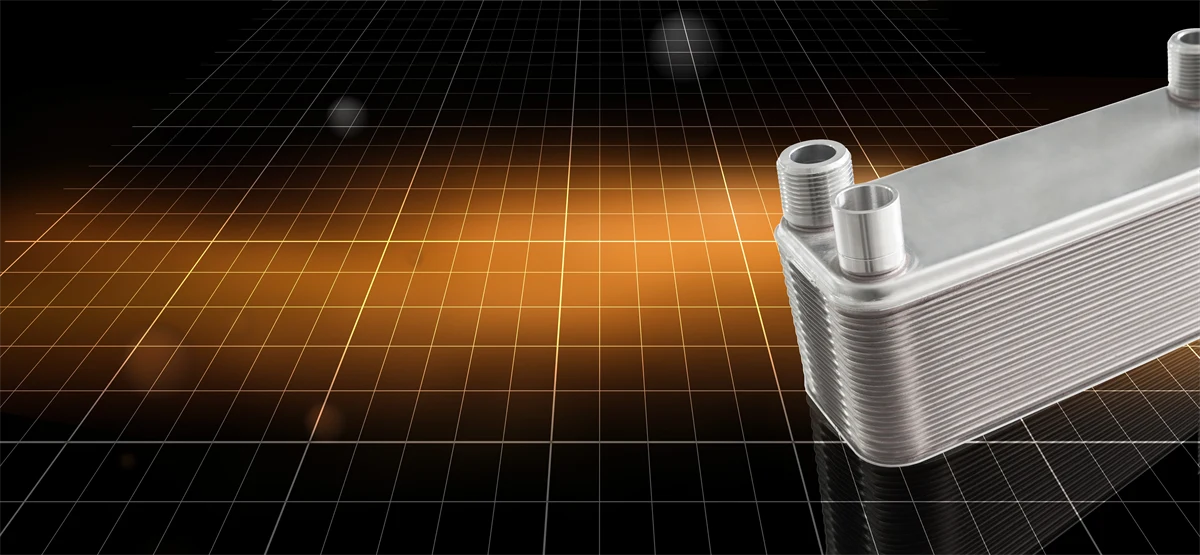

Höganäs – your preferred brazing partner

Höganäs offer you our full-service expertise and materials that meet your exact requirements. By working closely with you, we can shorten your time to market, efficiently automate paste application solutions and also improve your quality, yield and productivity in order to offer the lowest total costs for your solutions.

Our skilled and experienced brazing team has the capacity and application knowledge required to turn brazing filler metals into optimum brazing paste solutions. Apart from development of new products, our services include metallography, analysis and problem solving, and through the use of our Customer Development Centre, our team offers material development, application design and prototyping, as well as process optimization.

Höganäs has established a global technical support network that provides in-house as well as on-site services to ensure that your brazing solution consistently generates good results.

Our services cover five areas to support you in achieving the best brazing result:

-

Application development: We support you in defining the brazing filler metal and braze joint properties. By working closely with our customers' applications, we have gained extensive knowledge, experience with application requirements and insights into the latest industry trends.

-

Filler metal application: Choose from our broad portfolio of BrazeLet® filler metals. We offer a full range of nickel (Ni) and iron (Fe)-based BrazeLet filler metals for high temperature brazing, including powders and pastes.

-

Paste application: Höganäs helps you find the best application method for your brazed components. Our state-of-the-art tech centres enable pilot scale production tests using your components.

-

Brazing process: We help you in making your process as efficient as possible. Whether you want to evaluate your brazing results or find the root cause of poor components or low brazing performance, Höganäs’ brazing experts are available to help you improve your process and increase your value.

-

Continuous improvements: Expect lifetime consultancy for your total quality management. Our support doesn’t end once the project is in production. We provide continuous production improvements to our customers, in order to maximize their value.

Personuppgiftspolicy

Jag godkänner att Höganäs hanterar mina personuppgifter för att kontakta mig. Min kontaktinformation kan även komma att användas för marknadsföringsändamål, som nyhetsbrev och annan relevant information. Uppgifterna kommer inte att delas med någon tredje part. I och med detta samtycke bekräftar jag även att jag är över 16 år.

Mer information om hur vi hanterar personuppgifter anges i vår personuppgiftspolicy.