Powder Metallurgy

a process with many advantages

This is Powder Metallurgy!

The powder metallurgy process has many advantages compared to other metal forming technologies such as forging, metal casting or machining. The first advantage is cost effectiveness. With powder metallurgy you greatly reduce post-production processes such as metal removal procedures. This drastically reduces yield losses in manufacture and thereby lower total costs. In addition, the process has a lower energy consumption in comparison to other production technologies.

The second main benefit of powder metallurgy is the possibility to deliver product uniqueness thanks to high flexibility. It is possible to tailor alloys and physical characteristics to match specific properties or performance requirements. By producing parts with repeatable homogeneous material structures, the powder metallurgy process allows to manufacture structural metal components with high predictability and consistency of mechanical behaviour for a wide range of applications.

Powder metallurgy is used to make unique materials with tailored properties, impossible to achieve from melting or forming with other methods. It enables combinations of materials that would otherwise be impossible to mix and processing of materials with very high melting points. There are also advantages when it comes to creating complex shapes or integrating additional design features or functionalities in one part.

The flexibility of powder metallurgy includes:

- Controlled porosity

- Tailored strength and performance levels

- Isotropic properties but also allowing graded materials or selectively densified sections

- Noise reducing or damping of vibrations

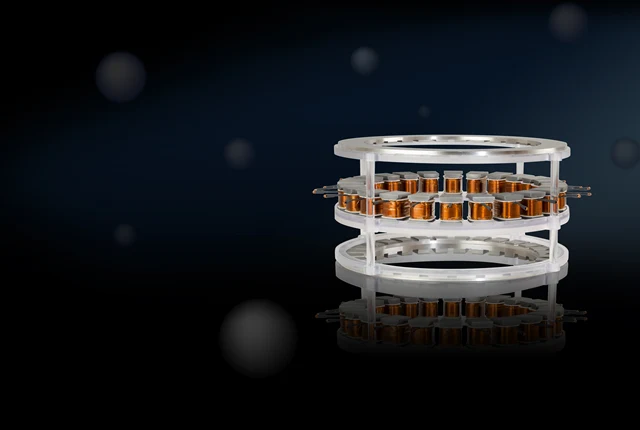

- Unique magnetic properties

- Excellent surface finish

- High repeatability of high precision in large production series

- Excellent wear resistance

Powder metallurgy comprises several different production technologies. The press-and-sinter process is the most common and consists of three basic steps: powder atomisation with subsequent mixing and blending of elemental or alloyed powders, die compaction under controlled compaction pressures, and sintering in controlled atmospheres. Other important production technologies include metal injection moulding (MIM), isostatic pressing (hot or cold), powder forging and metal additive manufacturing.