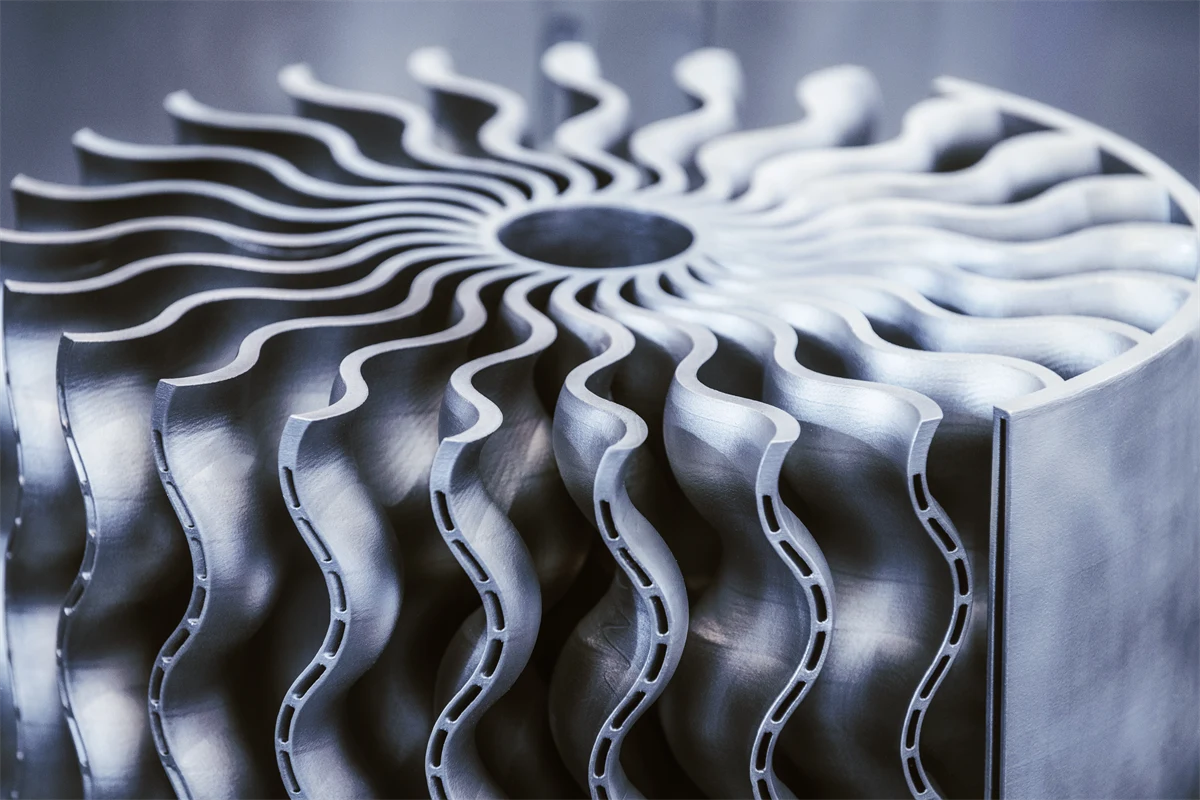

Additive manufacturing

– features

Water atomised powders

This cost-effective production technique is currently used to produce low-alloy iron and steel powders for pressing and sintering. But it also has great potential for additive manufacturing. Höganäs is driving this development, testing powders that could provide a more cost-efficient alternative for 3D printing.

Höganäs is investing in a new fine powder facility in Johnstown, Pennsylvania in the United States. The purpose is to expand the company’s production capacity of metal powders within additive manufacturing, surface coating and metal injection moulding. Construction of the production site is under way and market introduction of these powders is planned to take place in the first half of 2021.

Personuppgiftspolicy

Jag godkänner att Höganäs hanterar mina personuppgifter för att kontakta mig. Min kontaktinformation kan även komma att användas för marknadsföringsändamål, som nyhetsbrev och annan relevant information. Uppgifterna kommer inte att delas med någon tredje part. I och med detta samtycke bekräftar jag även att jag är över 16 år.

Mer information om hur vi hanterar personuppgifter anges i vår personuppgiftspolicy.