推动汽车创新的动力

汽车和运输

可持续汽车解决方案

随着汽车和运输行业不断向更绿色、更智能、更光明的未来前进,我们看到,金属粉末技术走在了这个进步时代的前列。

Höganäs正与汽车制造商建立密切的合作关系,不仅提供优质的金属粉末,还能满足一系列应用需求。 我们的解决方案可提高性能,并为电气化提供助力。

压制和烧结汽车零部件的种类越来越丰富,针对这些部件设计经济有效的粉末冶金解决方案仍然是我们的工作重点。 但Höganäs在该领域增材制造金属粉末方面也处于先锋地位,开发功能原型和备用件。

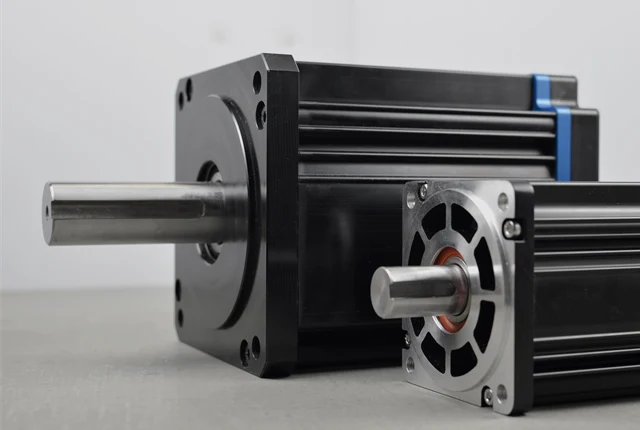

我们是高温钎焊市场的领导者,提供优质的钎焊膏以及将技术和发展潜力结合在一起的深厚的专业知识和技术。 此外,我们的电感器、电动机和动力传动系统解决方案——采用优质的软磁复合材料粉末制造——让客户可以进行更灵活、更紧凑的电子设计,帮助满足对小型电动机和混合电动机日益增长的需求。

我们的目标是扩大因金属粉末技术而受益的应用领域范围,为汽车和运输制造业拥有一个更具成本效益的可持续发展的未来开辟新的机遇。

我们的主要专业领域

- 汽车行业、该行业所面临的挑战、应用需求以及生产工艺方面的专业知识和经验。

- 用于电磁和摩擦应用、压制和烧结、钎焊、热表面涂层、3D打印以及电感器解决方案的定制金属粉末。

- 可持续的开创性解决方案,帮助满足对电气化、混合、降低废品率和减少碳排放的需求。

- 从概念到应用阶段与客户建立密切的合作关系, 以加快产品上市为目标。

汽车应用

汽车行业是推动材料创新的动力,该领域的金属粉末应用日益增长。

我们的解决方案可使部件更轻、性能更出色并且更耐用,从小零件到形状较复杂的大部件都适合使用。 这些解决方案将成本效益和创新结合在一起,有助于为汽车电气化提供支持。

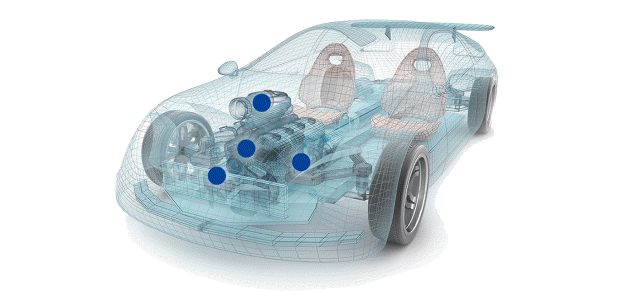

想象一款完全用金属粉末打造的汽车

烧结零件已广泛用于现代变速箱和发动机系统中。 但金属粉末也是钎焊、热喷涂以及增材制造等技术的理想选择。

借助我们的软磁复合材料解决方案,我们将帮助您满足电动汽车和混合动力汽车领域对经济高效的电磁应用日益增长的需求。

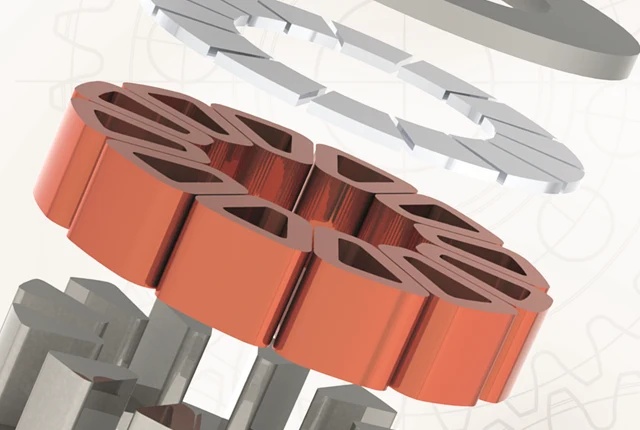

电机中的软磁复合材料

电机几乎影响着现代社会的各个方面。 它们应用在大多数工业生产过程中,在某种程度上,现代工厂中生产的几乎任何产品都会用到电机。 电吹风、风扇、空调、冰箱和冷冻柜、吸尘器、食品搅拌机以及日常生活中使用的许多其他家用电器都是利用电机将电能转换为机械能的。

现在,电机还迅速成为未来混合动力和纯电动汽车的基础,此外它还可以作为诸如泵和A/C压缩机等机械辅助系统的电驱动源。

粉末冶金斜齿轮的优势

斜齿轮用于需要较高啮合系数的齿轮应用中,可以降低噪声和应力。 使用粉末冶金技术实现了高达36度的螺旋角的斜齿轮的批量生产。 设计了非常先进的齿轮几何形状,可近净成形压制。 这样可以 减轻重量并增加其他特性,如花键、零件号识别、装配功能设计等等。

所有这些均无需任何机加工即可实现。 粉末冶金这种成熟的环保技术为降低单个零件成本、增加价值开创了新机遇。

获得灵感

金属粉末有助于可持续发展

金属粉末技术提供无限机遇,不仅能够帮助我们的客户降低材料和能源消耗,还能帮助他们使用更好的新技术,使最终产品更高效、更便宜。

我们相信,因为金属粉末的固有能力,金属粉末的用途远比现在的用途更广泛。 我们也坚信,金属粉末能够促进可持续发展。通过金属粉末解决方案,我们可以为解决社会所面临的很多紧迫的挑战做出自己的贡献,如资源缺乏以及对可再生能源的需求。