自動車技術革新を推進

自動車・輸送機器

革新的な自動車向けソリューション

自動車業界と輸送機器業界が、よりスマートでより明るい未来に向かって進歩するにあたり、金属粉技術はこの進歩的な時代の最前線で貢献します。

Höganäsは、自動車メーカーとの強力なパートナーシップを構築し、高品質な金属粉だけでなく、さまざまな用途に対応するソリューションを提供しています。 弊社のソリューションは性能を向上させ、持続可能性の目標達成や電動化を支援します。

多様化する自動車向け焼結部品製造の費用対効果の高い粉末冶金分野は、引き続き私たちの事業の中心となっています。 Höganäsはこの分野でも機能試験まで可能な試作品やスペアパーツ用途開発に3Dプリンティング用金属粉を先駆けて提供しています。

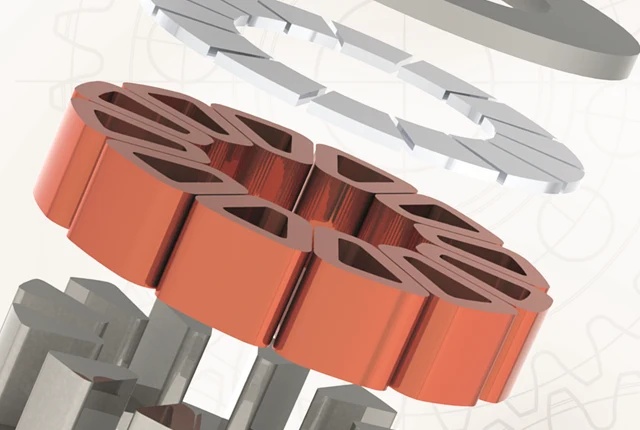

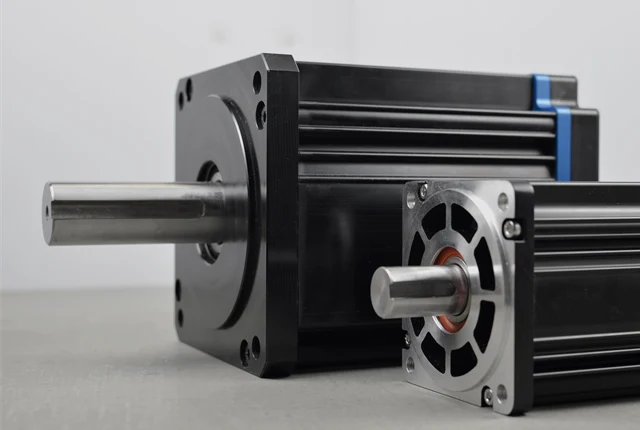

弊社は高温ろう付けのマーケットリーダーであり、優れたペーストろう材と接合技術における深い専門知識や新しい可能性を提供します。 さらに、弊社の優れた軟磁性複合材料を使用したインダクタ、電動モータおよびドライブトレインのソリューションは、柔軟でより小型な電子設計を可能にし、小型の電気およびハイブリッドモータに対する需要の増大にも対応しています。

私たちの目標は、金属粉技術を活用できる用途の範囲を広げ、自動車製造業や輸送機器関連の製造業などにおいて、よりコスト効率の高い、持続可能な未来への新たな機会を開くことです。

主な専門分野

- 自動車産業における課題、様々な用途での要求事項や製造工程に関するノウハウと経験。

- 電磁気および耐摩耗用途、プレス成形・焼結、ろう付け、表面処理、3Dプリンティングおよびインダクタソリューション各用途にカスタマイズされた金属粉

- 電動化、ハイブリッド化、スクラップ率の低減、および炭素排出量の削減の要求を満たすための先駆的かつ持続可能なソリューション。

- 市場投入までの時間短縮化を目的としたコンセプト設計から実用化までのお客様との密接なパートナーシップ

自動車用途

自動車産業は材料革新の推進役で、そこでの金属粉の用途は日々拡大しています。

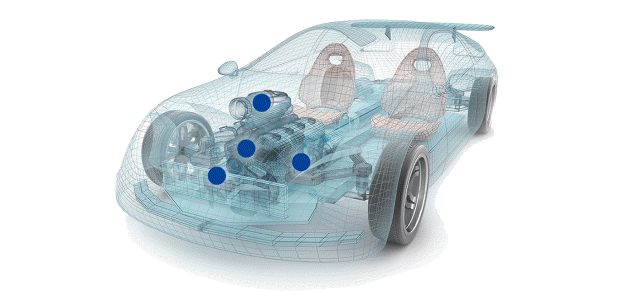

軽量化、優れた性能、そして耐久性を提供するソリューションは、小型部品からより複雑な形状の大型部品まで、あらゆる用途で使用できます。 金属粉は費用対効果が高く、技術革新を可能にし、自動車の電動化にも貢献しています。

金属粉粉の技術をフルに活用した自動車をご想像ください

焼結部品は、現代のトランスミッションおよびエンジンシステムで既に幅広く採用されています。 金属粉は、更にろう付け、表面処理、積層造形などの技術にも理想的な材料です。

弊社の軟磁性複合材料ソリューションは、電気自動車やハイブリッド自動車における費用対効果の高い電磁気部品用途の需要の増加に対応します。

電気モータ用軟磁性複合材料

電気モータは現代社会のほとんどすべての側面に影響を与えています。 電気モータは、あらゆる工業工程や現代の工場で製造されるほぼすべての製品に使用されています。 ヘアドライヤー、扇風機、エアコン、冷蔵庫、冷凍庫、掃除機、ブレンダー、そして私たちが日常生活で使用している他の多くの電化製品では、電気エネルギーを機械エネルギーに変換するために電気モータが使用されています。

また、電気モータは、将来の輸送機器の基盤となるハイブリッド車およびバッテリー式電気自動車の駆動源として、また、ポンプおよびエアコン用コンプレッサーなどの補機システムの従来型機械的駆動方式に代わる動力源としてとして急速に確立されています。

粉末治金によるヘリカルギヤ製造の利点

ヘリカルギヤは、騒音や応力の低減のために高い接触比を必要とする場合に使用されます。 粉末治金技術を使用することにより、現在量産で36度のねじれ角まで製造できます。 極めて先進的な歯車の本体形状を設計し、ネットシェイプまたはニアネットシェイプの形状をプレス成形することができます。 軽量化に加え、スプライン、部品識別番号、アセンブリ機能などを設計に追加することが可能になります。

これらはすべて二次的な機械加工を必要としません。 粉末治金はグリーン技術として、製品単価を引き下げ、価値を高める機会を提供します。

インスピレーションを得る

金属粉による技術を第一の選択肢にする

製品開発と事業化を成功させるには、材料、工程、設計を密接に結びつけることが重要です。 Höganäsでは、PoPセンターでの緊密な協力関係を介してこれを実現しています。

金属粉末は持続可能な成長に貢献します

金属粉の技術は無限の力を秘めています。材料とエネルギー消費を削減するだけでなく、最終製品を効率的に低コストで製造出来る新しくて優れた技術を使用することができます。

私たちは、金属粉の可能性は、現在利用されているよりもはるかに幅広く活用できるものだと信じています。 また、金属粉が持続可能な開発に貢献できることに確信を持っています。金属粉末ソリューションを使用することで、資源の不足、再生可能エネルギーの必要性など、社会が直面している多くの課題を解決することに貢献できます。