粉末溶接用ニッケル系粉末

Surfit®ニッケル (Ni) 系粉末

Surfit 1015-00 | Ni <0.06C 2Si 1.1B 0.5Fe 20Cu | 106/20 µm

粒度: 106/20 µm

化学成分: Ni <0.06C 2Si 1.1B 0.5Fe 20Cu

粉末タイプ: ガスアトマイズ法

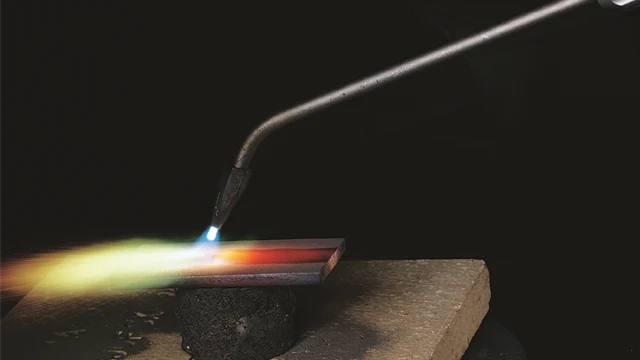

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1020-00 | Ni <0.06C 2.3Si 1.4B 0.4Fe | 106/20 µm

粒度: 106/20 µm

化学成分: Ni <0.06C 2.3Si 1.4B 0.4Fe

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1021-10 | Ni <0.05C 2Si 0.7B 3Cr 2P | 106/20 µm

粒度: 106/20 µm

化学成分: Ni <0.05C 2Si 0.7B 3Cr 2P

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1121-10 | Ni <0.05C 2Si 0.7B 3Cr 2P | 71/20 µm

粒度: 71/20 µm

化学成分: Ni <0.05C 2Si 0.7B 3Cr 2P

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1023-00 | Ni <0.06C 2.5Si 1.6B | 106/20 µm

粒度: 106/20 µm

化学成分: Ni <0.06C 2.5Si 1.6B

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1025-40 | Ni <0.06C 2.7Si 1.8B | 106/20 µm

粒度: 106/20 µm

化学成分: Ni <0.06C 2.7Si 1.8B

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1031-10 | Ni <0.05C 2.2Si 0.9B 3Cr 2.2P | 106/20 µm

粒度: 106/20 µm

化学成分: Ni <0.05C 2.2Si 0.9B 3Cr 2.2P

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1035-40 | Ni 0.32C 3.7Si 1.2B 3Fe 7Cr | 106/20 µm

粒度: 106/20 µm

化学成分: Ni 0.32C 3.7Si 1.2B 3Fe 7Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1135-40 | Ni 0.32C 3.7Si 1.2B 3Fe 7Cr | 71/20 µm

粒度: 71/20 µm

化学成分: Ni 0.32C 3.7Si 1.2B 3Fe 7Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1036-40 | Ni 0.15C 2.8Si 1.2B 4.5Cr 2.5Mo 1.9P | 106/20 µm

粒度: 106/20 µm

化学成分: Ni 0.15C 2.8Si 1.2B 4.5Cr 2.5Mo 1.9P

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1136-55 | Ni 0.15C 2.8Si 1.2B 4.5Cr 2.5Mo 2.1P | 71/20 µm

粒度: 71/20 µm

化学成分: Ni 0.15C 2.8Si 1.2B 4.5Cr 2.5Mo 2.1P

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1038-40 | Ni <0.07C 3Si 2.3B <0.8Fe | 106/20 µm

粒度: 106/20 µm

化学成分:Ni <0.07C 3Si 2.3B <0.8Fe

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1040-00 | Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr | 106/20 µm

粒度: 106/20 µm

化学成分: Ni 0.25C 3.5Si 1.6B 2.5Fe 7.5Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1045-00 | Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr | 106/20 µm

粒度: 106/20 µm

化学成分: Ni 0.35C 3.6Si 1.9B 2.7Fe 9Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1050-00 | Ni 0.45C 3.8Si 2.2B 2.9Fe 11Cr | 106/20 µm

粒度: 106/20 µm

化学成分: Ni 0.45C 3.8Si 2.2B 2.9Fe 11Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1055-20 | Ni 0.55C 4Si 3.4B 2.7Fe 16Cr 3Mo 3Cu | 106/20 µm

粒度: 106/20 µm

化学成分: Ni 0.55C 4Si 3.4B 2.7Fe 16Cr 3Mo 3Cu

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 1060-00 | Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr | 106/20 µm

粒度: 106/20 µm

化学成分: Ni 0.75C 4.3Si 3.2B 3.8Fe 14.8Cr

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

|

備考:

|

||

Surfit 602P | Ni 0.65C 4.2Si 2.9B 4.3Fe 13.1Cr | -150 メッシュ

粒度:-150 メッシュ

化学成分: Ni 0.65C 4.2Si 2.9B 4.3Fe 13.1Cr

粉末タイプ: 水アトマイズ法

通常使用される成膜技術:

|

備考:

|

||

Surfit 1623-05 | Ni 0.03C 2.5Si 1.6B 0.35Fe | 53/20 µm

粒度: 53/20 µm

化学成分: Ni 0.03C 2.5Si 1.6B 0.35Fe

粉末タイプ: ガスアトマイズ法

通常使用される成膜技術:粉体溶接

Surfit® Ni 自溶性合金 + カーバイド混合

Höganäs は、ニッケル自溶性(SF)合金とタングステン・カーバイドの幅広い種類のSurfit混合物粉末を提供します。

ニッケル自溶性合金の幅広いポートフォリオと、さまざまなタングステンカーバイドを組み合わせることで、用途の要件に合わせて調合できます。

- ニッケル自溶性合金

- Amperweld® タングステンカーバイド

- Amperweld CTC - キャストタングステンカーバイド

- Amperweld SCTC - 球状タングステンカーバイド

- Amperweld MTC - Macroline タングステンカーバイド

- Amperit® タングステンカーバイドコバルト

- Amperit 519 WC-Co 88-12

- Amperit 526 WC-Co 83-17

用途に合ったSurfit混合物粉末は、 Höganäs 営業担当者にお問い合わせください。

粒度: -

化学成分: -

粉末タイプ: 混合

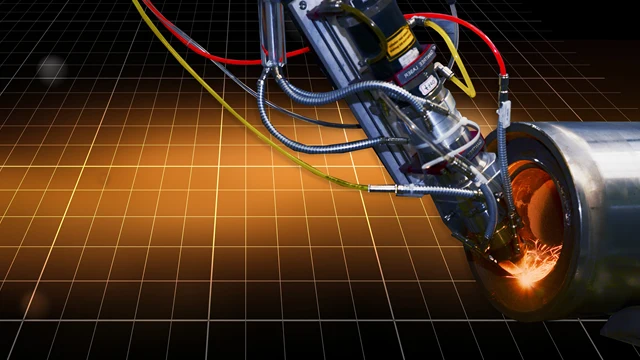

通常使用される成膜技術:フレーム溶射,HVOF,レーザークラッディング,粉体プラズマアーク溶接(PTA),粉末溶接

Surfit® 硬質相粉末

Surfit® Ni 自溶性合金 + カーバイド混合

Höganäs は、ニッケル自溶性(SF)合金とタングステン・カーバイドの幅広い種類のSurfit混合物粉末を提供します。

ニッケル自溶性合金の幅広いポートフォリオと、さまざまなタングステンカーバイドを組み合わせることで、用途の要件に合わせて調合できます。

- ニッケル自溶性合金

- Amperweld® タングステンカーバイド

- Amperweld CTC - キャストタングステンカーバイド

- Amperweld SCTC - 球状タングステンカーバイド

- Amperweld MTC - Macroline タングステンカーバイド

- Amperit® タングステンカーバイドコバルト

- Amperit 519 WC-Co 88-12

- Amperit 526 WC-Co 83-17

用途に合ったSurfit混合物粉末は、 Höganäs 営業担当者にお問い合わせください。

粒度: -

化学成分: -

粉末タイプ: 混合

通常使用される成膜技術:フレーム溶射,HVOF,レーザークラッディング,粉体プラズマアーク溶接(PTA),粉末溶接

お問い合わせ

Sales & Technical support

プライバシー保護に関する方針

私は、ヘガネスが、私と連絡をとる目的で、私の個人データを利用することに同意します。 また、私の連絡先情報をニュースレターやその他関連情報といったマーケティング目的に使用することに同意します。 データが第三者と共有されることはありません。 また、16歳以上であることを認めます。

個人情報の取扱いに関する詳細は、弊社のプライバシー保護方針でご確認いただけます。