3Dプリンティング(積層造形)

- 特徴

VIGAが高品質の金属3Dプリンティング用粉末製造でどのように使用されるか

真空誘導溶解不活性ガスアトマイズ法(VIGA)

不活性ガスアトマイズ法あるいはVIGA溶解真空誘導法は、大量の球状高グレード金属粉の生産で、主要な粉末製造プロセスの1つです。 高品質のコバルト基, ニッケル基、と鉄ベースの弊社forAM®金属粉は、専用のVIGAシステムにて製造しており、特に積層造形の必要条件に合わせて設計されています。

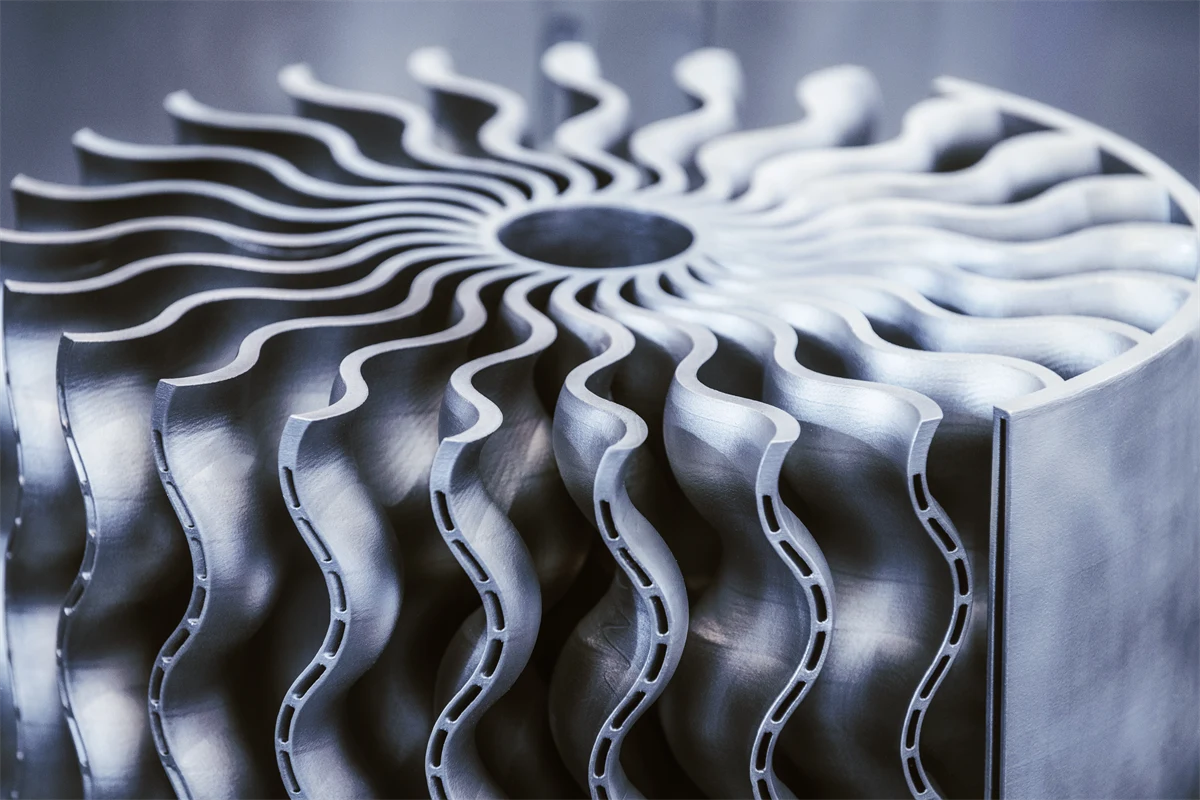

VIGAは、工程の信頼度と生産性に優れ、少ない運転費用が特徴の柔軟性を有した最先端技術の生産方式です。 私たちは、VIGAシステムにより、一貫して低酸素濃度かつ低いまたは調節された窒素濃度で、統合されたサテライト防止システムにより非常にサテライトが少ない球状粒子の高品質の粉末を製造できます。 更に、積層造形用粉末は高純度で、優れた流動性を持っており、粒径分布(PSD)がきちんと定義されています。

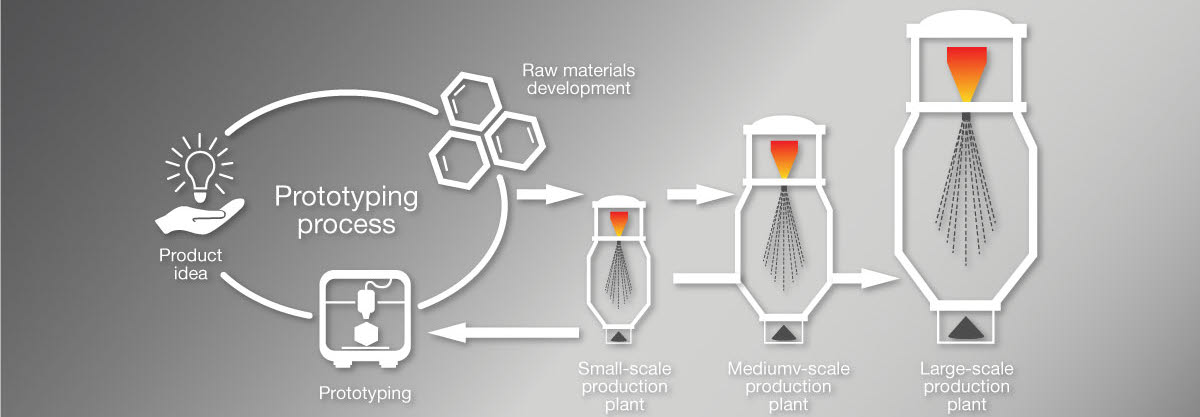

真空不活性ガスアトマイズ法により、お客様固有のカスタム3D金属粉を、実験室レベルから、中規模又は工業規模生産まで、どのような量でも規模を拡張して生産できます。弊社はお客様の製品開発を様々な段階でご支援致します。

VIGAの技術を使用した積層造形用粉末の主な用途は、産業用ガスタービン(IGT)の他、航空宇宙産業や医療産業などです。 VIGAは、ニッケル超合金、コバルト・クロム、工具鋼およびステンレス鋼の粉末生産に適します。

私たちの深化した粉末冶金のノウハウとVIGAシステムにより、お客様固有のアプリケーションに向けた3Dプリンティング用金属粉を提供できることを意味します。

プライバシー保護に関する方針

私は、ヘガネスが、私と連絡をとる目的で、私の個人データを利用することに同意します。 また、私の連絡先情報をニュースレターやその他関連情報といったマーケティング目的に使用することに同意します。 データが第三者と共有されることはありません。 また、16歳以上であることを認めます。

個人情報の取扱いに関する詳細は、弊社のプライバシー保護方針でご確認いただけます。