Additive manufacturing

– features

How VIGA is used to obtain high-quality metal 3D printing powder

Vacuum induction melting Inert Gas Atomization (VIGA)

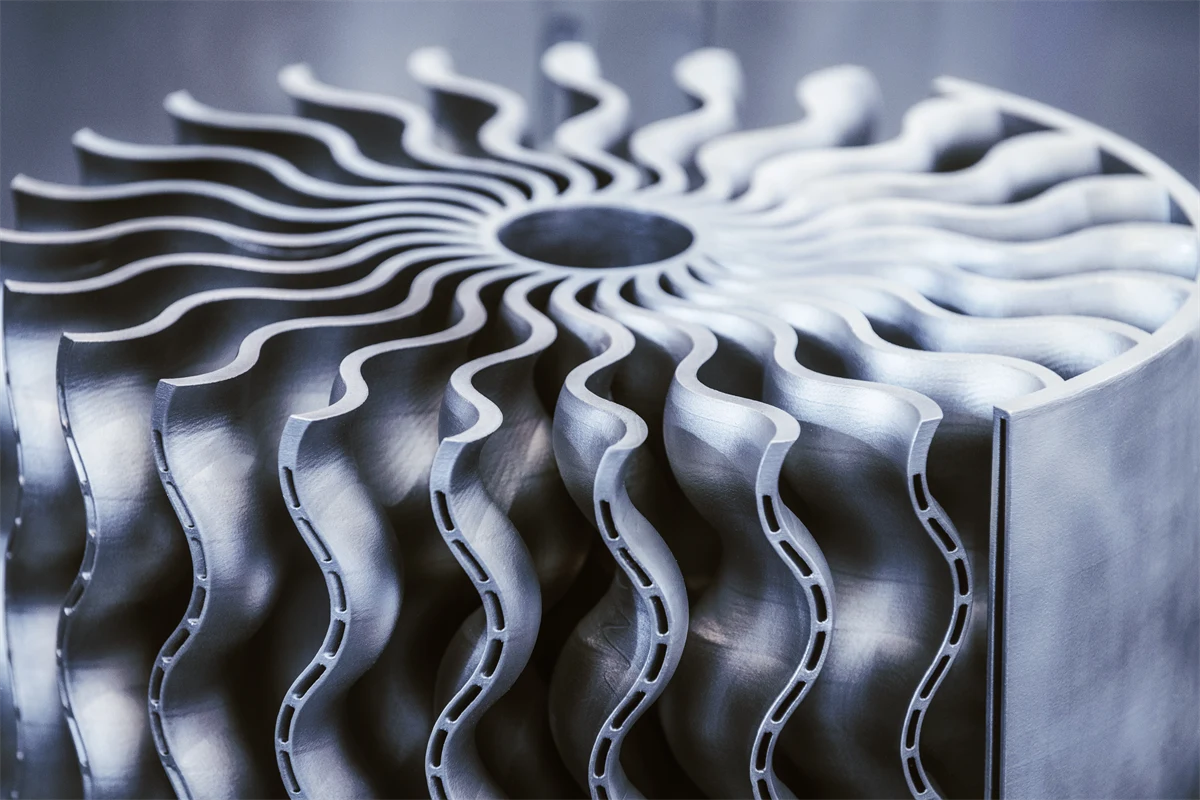

Vacuum induction melting Inert Gas Atomization or VIGA is one of the leading powder-making processes for production of large volumes of spherical, high-grade metal powders. Our high-quality cobalt-, nickel- and iron-based forAM® metal powders are produced with the specific VIGA system and have been designed specifically for the requirements of additive manufacturing.

VIGA is a flexible state-of-the-art production method characterized by process reliability, good productivity and low operating cost. Thanks to the VIGA system, we can consistently produce high-quality powders with low oxygen and low or adjusted nitrogen concentration, spherical particles, and very low satellite due to the integrated anti-satellite system. Furthermore, the additive manufacturing powders are of high purity, have good flow characteristics and defined particle size distributions (PSDs).

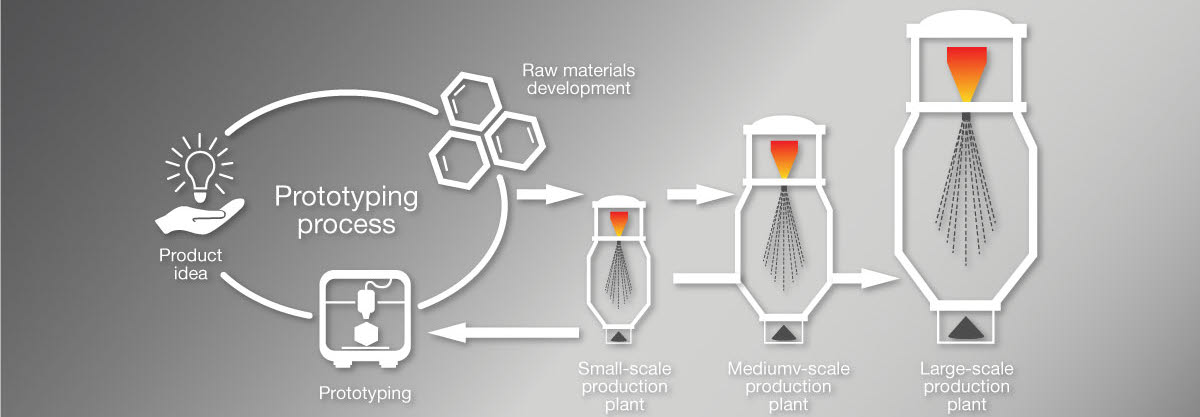

In our vacuum induction melting inert gas atomization process, we can produce any quantity of customized 3D metal powder, from lab scale up to medium or industrial scale production to support you through the various stages of your product development.

The main applications for additive manufacturing powder produced using the VIGA technology can be found in the Aerospace and Medical industries, as well as for industrial gas turbines (IGT). VIGA is suitable for producing nickel super alloys, cobalt chromium powders, tool steels and stainless steels.

The VIGA system combined with our deep metallurgical know-how means that we can offer you the right 3D printing metal powder for your specific applications.

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.