Deposition techniques

Versatile welding with plasma transferred arc

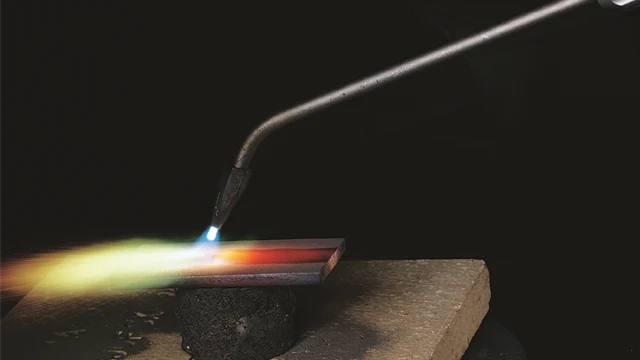

Plasma transferred arc is a surface welding method, which enables a metallurgical bonding with the base material. It is versatile as it can be used on most alloys.

The high-energy plasma transferred arc melts the surface of the base material. At the same time, the metal powder is inserted into the arc where it is molten. A substance-to-substance bond is created between the filler material and the base material during solidification.

The method can be fully automated and once the parameters are fixed for a certain design, consistent final results are achieved for all pieces.

The process is applied to many different components in a wide range of industries such as in the Oil & Gas, Automotive and Energy industries.

Plasma transferred arc or PTA is ideal for automated high-volume applications, such as thermal surfacing of exhaust valves. The technique offers low-base metal dilution and can be used with a wide range of consumables.

Typical working range

Typical working range

- Deposition rate: 2-12 kg/hour

- Deposition thickness: 1 - 6 mm

- Deposition hardness: up to 68 HRC

Benefits

- Suitable for automation

- 1-6 mm thickness

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

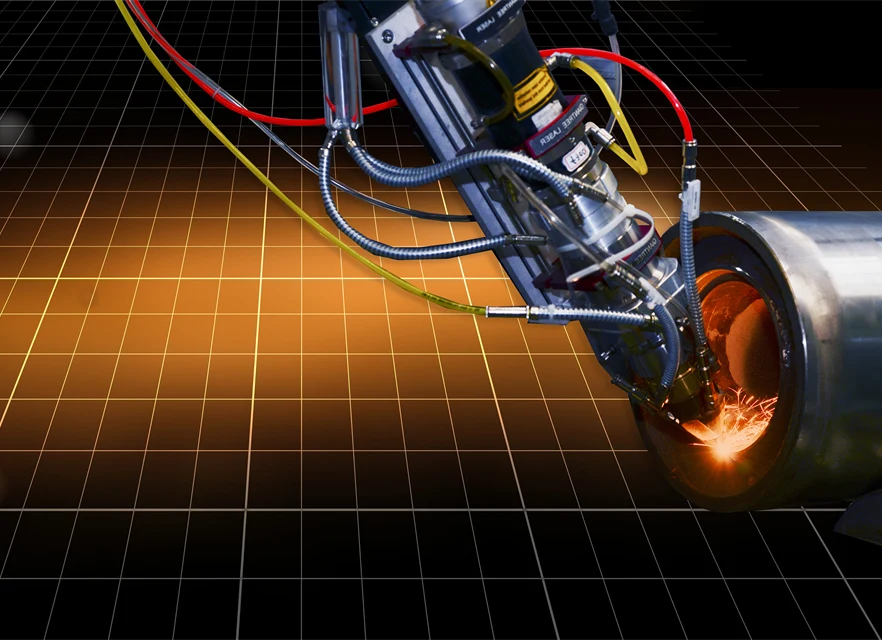

ArcX coating hub

ArcX – Your starting point for innovation

Expert know-how in materials, surface welding and flame spraying processes and customer applications make our ArcX technology centres an exclusive resource in your work to optimise existing applications and develop new business opportunities.