Get extreme

– use Rockit®

Combat impact, abrasive wear and corrosion with Rockit

Rockit 606/706 – improved impact and abrasive wear resistance

Rockit 606/706 are designed to improve the performance and lifetime of components operating in environments where both impact and severe abrasive wear occur.

Abrasive wear dominates many applications and the current industrial solution is to use MMCs (metal matrix carbides) such as NiCrBSi/WC. However, the impact wear resistance tends to be low, as high abrasive wear resistant materials are brittle by nature.

Rockit 606 and Rockit 706 feature a unique combination of high impact and abrasive wear resistance and are robust to process variations.

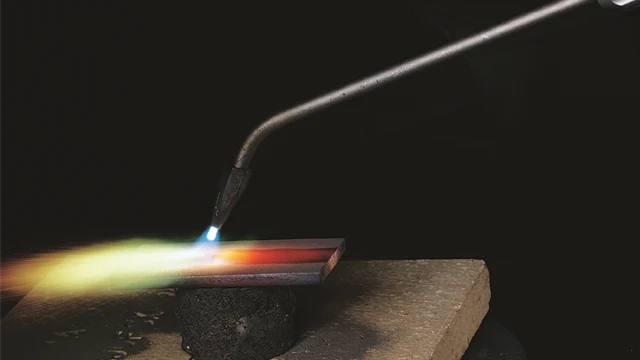

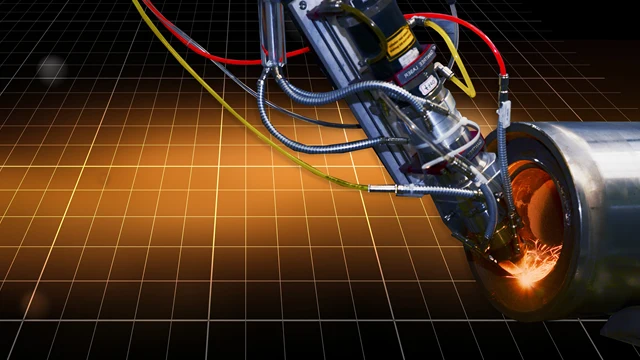

The recommended choice for laser cladding is Rockit 606, while Rockit 706 is ideal for the Plasma Transferred Arc (PTA) welding process.

If you’re looking for a solid AR steel solution, Rockit 606 and 706 are your preferred choice.

Main product features of Rockit 606/706:

- Excellent welding properties with nice and smooth deposit

- Homogenous hardness within deposition layers

- Exceptional impact and abrasive wear properties

Typical applications for Rockit 606/706:

- Oil & Gas: stabilizers, bent housings and drill bits

- Mining & Construction: Hydraulic cylinder parts, rotary vane wheels, crusher rolls & rings, ground engagement tools (GET) such as scraper blades, bucket lips and wear plates

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.