Deposition techniques

Extend component life with HVOF and HVAF coating

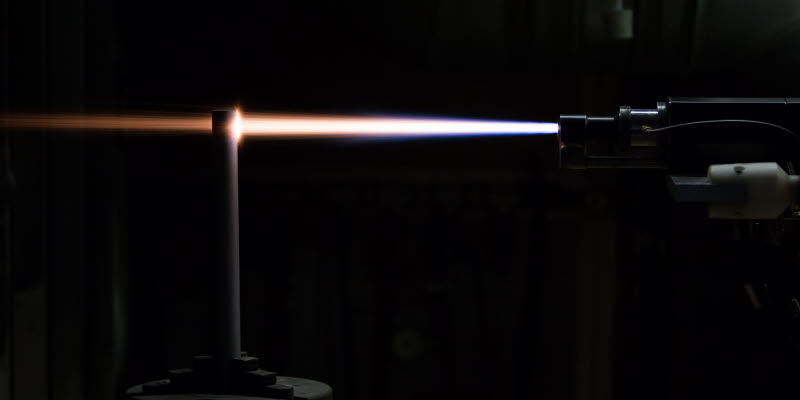

The HVOF and HVAF techniques are used to enhance surface properties of components. This way, a low-cost or light-weight material can be prepared with a functional and high-performing surface. The techniques can be used to repair and restore damaged components.

The HVOF and HVAF coating techniques are used to apply coating materials such as metals and alloys to produce exceptionally hard coatings with excellent adhesion to the substrate material.

HVOF and HVAF are both thermal spray systems using combustion of gases. HVOF spraying combines velocities up to 700 m/s and higher with moderate temperatures. This process provides a very dense coating (> 97%). Deposition rates are up to 9 kg/hour, and coating thicknesses range from 0.05 to 1 mm. The HVAF process uses a fuel gas such as propane, propylene or natural gas, and compressed air.

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

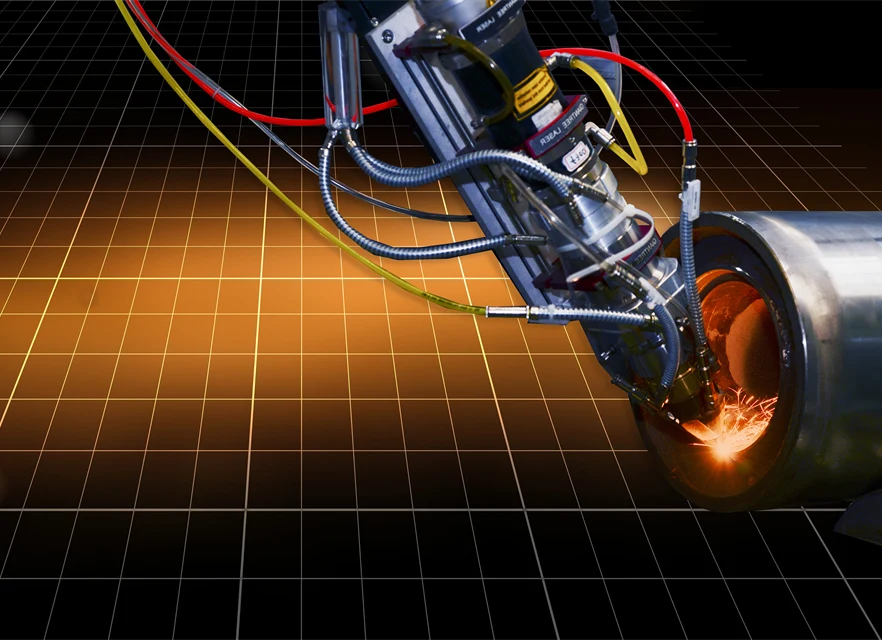

ArcX coating hub

ArcX – Your starting point for innovation

Expert know-how in materials, surface welding and flame spraying processes and customer applications make our ArcX technology centres an exclusive resource in your work to optimise existing applications and develop new business opportunities.