Pressing & Sintering

The gate for innovations

Metal powders for pressing and sintering

Powder mixes

Höganäs delivers powder solutions for the component manufacturer in press-ready flex-bags which are ideal for transporting and emptying directly onto your press for optimal performance.

Benefits

- Press-ready to your workshop

- Tailor-made properties to for best productivity, performance and cost

- Access to a wide range of different alloys and additives

- Worldwide support and service to optimise your performance

Base powders

Base powders are the main ingredient in any powder mix. Over the years we have developed a range of different alloy brands, now standards in the PM industry.

Four kinds of base powders

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

Tune up for top preformance

There are two fundamental ways to improve profit: reducing costs and increasing sales. We believe we can do both. Höganäs high precision Fe-Cu-C toolbox for improved operational excellence.

Moving forward with Chromium

To meet the automotive industry’s changing needs, new cost-effective materials and processes are required. Höganäs’ new product Astaloy® CrA is a pre-alloyed chromium material, for metal powder component production, that can be tailored to the customer’s needs and conditions.

Astaloy CrA, is a new developed product for PM with a versatility that meet these requirements.

Using chrome as an alloying element in low-alloy steel is nothing new, and Höganäs presented its first chrome-alloyed product Astaloy CrM in 1998. Chromium is an alloying element with several benefits over nickel and molybdenum, including better hardenability, low cost and stable cost-development.

Astaloy CrA already exhibits good mechanical properties after conventional sintering, but after the sinter-hardening process, the high performance is brought out in a cost-effective way.

The product may result in different microstructures, depending on which additional alloying elements and sintering processes choosed. It can easily be tailored to the customer’s requirements.

A real advantage

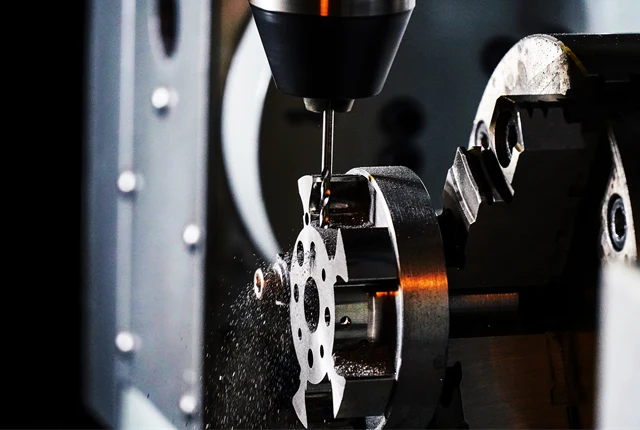

Astaloy CrA is used in production of synchronizer hubs. By admixing base material with graphite and nickel and utilizing the sinter-hardening process, you benefit from the product’s capacity regarding mechanical properties and dimensional stability.

With an eye to the future, Höganäs’ application experts have analyzed the development of automatic gearboxes to find suitable PM components and to meet the high standards of mechanical strength.