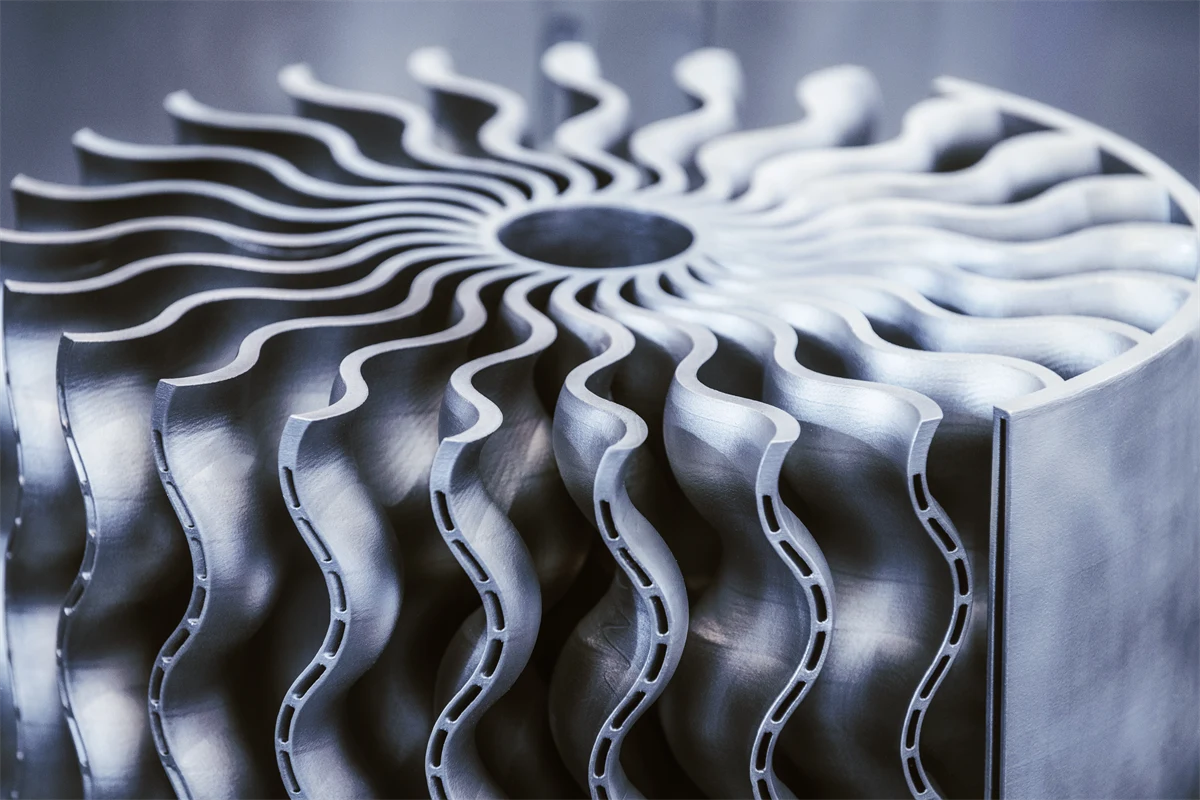

Additive manufacturing

– features

Plasma atomising

In Luleå, Sweden, you find our ground-breaking production unit where we are developing a new standard for spherical metal powders for 3D printing. Our production process is pioneering and we are working on optimising it for industrial scale.

Benefits of plasma atomised metal powder include:

- Full density, clean, highly spherical particles without satellites

- Widest selection of materials including metals, alloys, carbides, borides, inter-metallics and more

- Tailored particle microstructure

- Great potential for most demanding applications including aerospace, medical and oil & energy

- An innovative atomisation process that explores the limits in powder design and production

- Trial materials that can be supplied for selected projects

Contact form

Contact persons

Technical area:

Additive manufacturing

Select your country *

Type of contact *

Sales

Sales

Technical support

Firstname *

Lastname *

Company *

Field of work *

CEO/owner

Purchasing

Design engineer

Business developer

Machine operator

Other

E-mail *

Phone of work *

Your message *

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

You must accept the terms of service before you can proceed.