The drive for automotive innovation

Electric motors

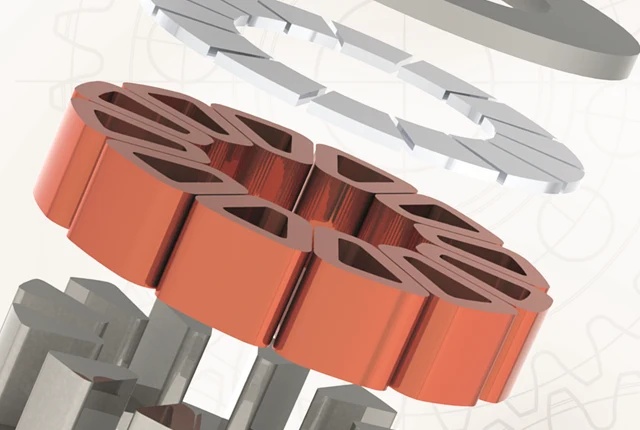

The basic operating principle of an electric motor hasn’t changed since the technology was invented in the 19th century. An electric motor consists of a moving element, the rotor, and a stationary element, the stator, which is permanently attached to the housing. When a current flows through the motor, the two elements have different magnetic fields, which repel each other. This causes the rotor and the rotor shaft to move.

There are a multitude of types of electric motors, which can be grouped depending on how they are powered (direct current, DC or alternating current, AC), the internal construction, application and type of motion output. In addition, they can be of various phase and be air-cooled or liquid-cooled.

Synchronous motors are commonly used for operating equipment that needs to be running at constant speed. Asynchronous motors are the most common form of an electric motor. They are widely used in industry applications thanks to their flexibility. Single-phase electric motors are used in domestic appliances such as portable power tools. Three-phase motors are used for hydraulic pumps, irrigation pumps and compressors. Constant, variable and adjustable speed motors are used in the marine and energy industries for cooling water pumps and air compressors. Brushless DC motors are commonly used in office products, such as laser printers or CD-drives. Universal motors are used in kitchen appliances, hair dryers and table fans.

Cost-efficient electric motor solutions

Making electromagnetic components of magnetic materials such as soft magnetic composite (SMC) enable the manufacture of more compact and cost-efficient electric motor solutions compared to using traditional designs.

SMC materials are made of iron powder particles coated with an electrically insulating layer and can be formed into complex shapes by means of powder metallurgy, thereby allowing three-dimensional magnetic circuit design.

The main benefits of SMC solutions for electric motor design are compact design, high performance and excellent cost efficiency.

Case studies

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.