Products

MIM stainless steel powders

The most common stainless steel material used by the metal injection moulding industry is 17-4PH. This precipitation hardening MIM steel combines high strength and hardness with corrosion resistance. Its attractive combination and good balance of properties makes it suitable for a wide range of applications, from automotive and tooling to IT segments.

If your application demands very high corrosion resistance, 316L is the right MIM stainless steel to choose. It is one of the most common stainless steels overall and often used in high demanding applications found in the medical, dental, luxury and IT related segments. It combines its extremely high corrosion resistance with medium strength.

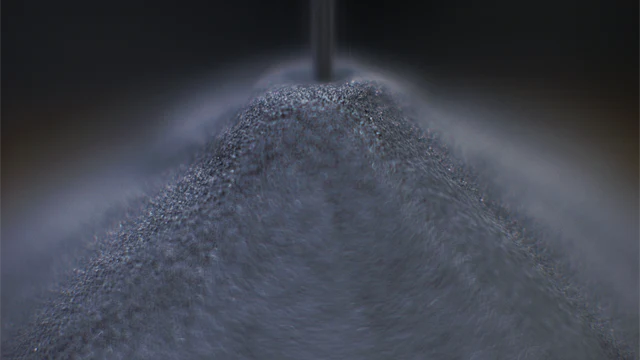

Our MIM stainless steels range include both powder and feedstock. With the vacuum induction melting inert gas atomisation technique, we can produce high-purity metal powders in a volume of your choice. VIGA is used for producing high-quality Co-, Ni- and Fe-based metal powders.

forMIM® stainless steel powders

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.