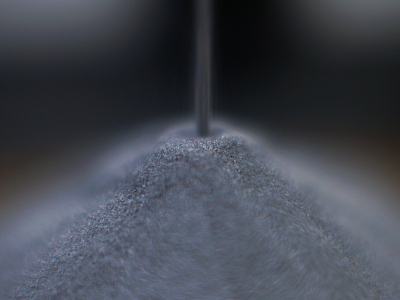

A wide range of iron powders

Using iron powder is a versatile and cost-effective way of producing durable precision components in complex shapes. The techniques where it is typically used include AM (additive manufacturing), brazing, chemical and metallurgical cutting, friction, HIP (hot isostatic pressing), pressing and sintering, and welding. Iron powder is also used in soft magnetic composites where it is well suited as core material for electrical motors.

Höganäs is famous for its consistent production of high-quality iron powder. We produce sponge iron powder and atomised iron powder from scrap metal. As the world’s leading metal powder company, Höganäs’ ambition is to be the preferred suppplier of sustainable metal powders in the world and to inspire and set the benchmark within our industry.

Find your iron powders at Höganäs:

Additive manufacturing iron-based powders

Additive manufacturing iron-based powders- Brazing

- Cutting iron powders

- Friction iron powders

- Hot isostatic pressing (HIP) iron-based powders

- Hot polymer filtration iron-based media

- Metal injection moulding (MIM) iron-based powders

- Pressing and sintering

- Soft magnetic iron powder

- Surface coating

- Welding iron powders

Metal powders contribute to sustainable development

Metal powder technology provides endless opportunities; not only does it enable our customers to reduce their material and energy consumption, but it also helps them use new and better techniques that make final products more efficient and less expensive.

We believe that the inherent power of metal powders can be utilised to a much larger extent than it is today. We are also convinced that metal powders can contribute to sustainable development. With metal powder solutions, we can contribute to solving many of society’s pressing challenges, such as resource scarcity and the need for renewable energy.