Climate

Climate and energy

Our objective is to become a net-zero company by 2037. This is a huge challenge but it is necessary. To minimize our climate footprint, we need to utilize both established and newly developed methods. We also need to invest in research and innovation to make improvements beyond what is possible today.

At present we are focussing on transitioning to renewable energy in production and transport, replacing fossil process coals, improving energy efficiency, and rethinking our materials supply.

Climate Roadmap

A strategic decision to become net-zero was approved by Group management in 2019. Since then, we have launched our Climate Roadmap, which shows the actions, priorities and investments that are needed to transform, based on our high ambition to become net-zero in our value chain by 2037. This includes rethinking our material and energy supply, our production processes, research and development plans and business models.

The Climate Roadmap consists of concrete action plans that are anchored at local level, consolidated at Group level and integrated in business planning processes. The plan is updated annually, and actions are frequently followed up to identify obstacles at an early stage and ensure that we make progress.

The integration of the Climate Roadmap into business plans and strategic decision-making is a key success factor to achieve climate adaption, together with co-operation with suppliers, customers and other business partners in our value chain.

The main building blocks to becoming fossil free in our own operations are:

- Move away from fossil fuels to renewable fuels and/or electrification

- Replace fossil metallurgical coke and anthracite with biochar

- Using fossil free electricity

To accomplish our target by 2030, we have identified three main areas:

- Replacing parts of our fossil-based coke and anthracite with biochar

- Replacing natural gas with biogas and switching to electrified vehicles or renewable fuels

- Buy all our electricity from fossil-free sources

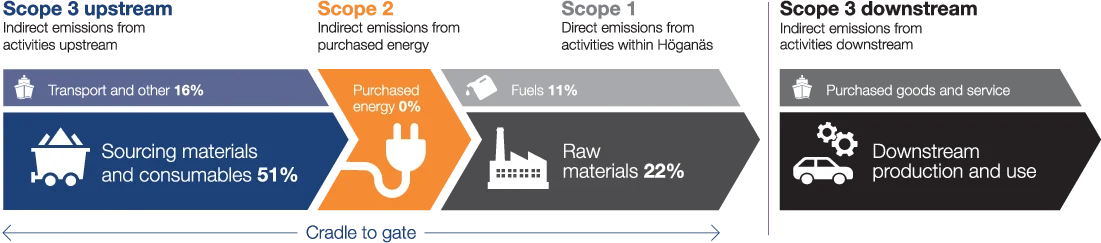

Höganäs' Climate Roadmap is based on the objective to become net-zero by 2037 and the scope covers both direct and indirect emissions.

Climate targets

*Net-zero is to reduce greenhouse gas emissions and, when there is no possibility to eliminate more emissions, neutralise remaining emissions with permanent carbon removal technologies. |

||

To achieve an emissions reduction of 30 percent in scope 3 related to our raw materials, it is necessary for us to co-operate with suppliers that have the objective to reduce their emissions. We will also follow our action plan to systematically inventory and replace all materials that we have identified as high emitters with low-carbon alternatives whenever available.

To achieve net-zero emissions in the value chain we also need to reduce the indirect emissions from the raw materials and transportation we purchase. To be able to do that, we need to ensure access to low carbon raw materials and transportation through our supply chain. We also need to co-operate with customers to utilise the benefits of the lowered carbon footprint of our own products in their applications.

We are dependent on external factors such as access to fossil free energy, biofuels and biochar, and technologies that can permanently remove carbon from the atmosphere (carbon capture and storage).

We also need intergovernmental incentives and agreements, as well as local and regional regulations that support the climate adaption of the industry, to be able to transform on such a large scale, while at the same time staying competitive.

The Climate Roadmap gives a good picture of the road ahead of us on a concrete and detailed level, based on the knowledge we have today. However, circumstances change rapidly, and new opportunities will open up as they are developed. The annual update of the plan will make sure that new knowledge is added and that new opportunities are continuously included in the plan.

Our progress when it comes to the Climate Roadmap is tracked on a quarterly basis through follow-ups of key activities and KPIs.

Climate reduction targets in line with latest science

Höganäs has become the first company in the metal powder industry, to have its climate impact reduction targets validated by the Science Based Targets initiative (SBTi). It can now ensure its climate actions are in line with the latest science.

Energy use

Höganäs’ energy use consists mainly of fuel consumption and purchased electricity and district heating. Natural gas is the largest source of non-renewable fuel energy used in our production processes. We also use diesel and petrol for vehicles and other engines, as well as LPG.

Surplus energy from our processes is converted into residual heat, which we deliver to external parties. Every year we deliver approximately 66,000 MWh in the form of surplus heat to district heating and municipal treatment plants in the Swedish cities of Höganäs and Halmstad, which saves the equivalent of 13,000 tonnes of carbon dioxide emissions compared with natural gas combustion.

We purchase approximately 487,900 MWh of electricity of which 57 percent is from renewable or partly renewable sources. We produce about 590 MWh of renewable electricity at our own facilities through solar panels.

New technique to produce renewable energy gas

There are currently few realistic alternatives to replace fossil fuels (naturals gas) for Höganäs, due to the need for precise process control, high temperature and purity. To initiate a change we started the Probiostål project and a collaboration with Cortus Energy who have developed the Woodroll® process, a technique for gasification and restructuring of biomass to renewable energy gas (renewable synthesis gas).

After a number of studies, a pilot plant was built at our site in Höganäs, Sweden, to perform tests on an industrial scale. If the technology is proven for use on an industrial scale, the installed unit alone will enable us to reduce our fossil CO2 emissions by about 10,000 tonnes per year.

Renewable raw materials

Fossil process coal used in our production is a challenge where we are taking the lead to become more renewable. The sponge iron plant is the only operation within the Group where we use fossil coke and anthracite to reduce iron ore into metallic iron. Today, the reduction process accounts for almost 70 per cent of the Höganäs Group’s direct CO2 emissions.

As part of our development programme for renewable alternatives we have identified and tested biochar as a replacement for some of the fossil coal. The ongoing development is promising and can, if successful, result in a reduction of up to 10 per cent of the Höganäs Group’s total direct emissions, or the equivalent of 28,000 tonnes of CO2 per year.

The pilot plant for renewable energy gas can also be used to produce bio-coke. This will enable us to evaluate biogenic process carbon from various renewable raw materials with the long-term objective to replace as much fossil carbon in the sponge iron process as possible.

Research to replace fossil coal

“The project will develop knowledge of bio-coal in order to replace as much fossil coal as possible in our manufacturing processes and at other companies in the industry,” says Ryan Robinson, engineer at Höganäs.

The research project is structured in three stages, which essentially means that the research team will draw up a specification for bio-coal for the two main processes at Höganäs for metal powder: the sponge iron process and the atomization process. They will then investigate the various process parameters for the production of bio-coal that meet the specifications. The third and final stage is to create a data model so that they can scale up the application more specifically in the sponge iron process. In parallel with this, Höganäs is carrying out practical trials to see how the material works on a larger scale.

Kentaro Umeki, Associate Professor at Luleå University, is project manager and is being assisted by two senior researchers and three doctoral students.

“We want to contribute to the development of a more sustainable society through our research. Höganäs is a serious, active partner that really wants to convert its production system, from its current use of large volumes of fossil coal to becoming fossil-free. If these climate goals are to be achieved, all companies in the steel industry must do the same. The environmental impact will be one of the most important criteria when consumers choose products, and it is extremely important for us to be able to choose products that are produced using green steel,” says Kentaro Umeki.

Case stories

“The project will develop knowledge of bio-coal in order to replace as much fossil coal as possible”

Ryan Robinson, engineer at Höganäs.

Climate