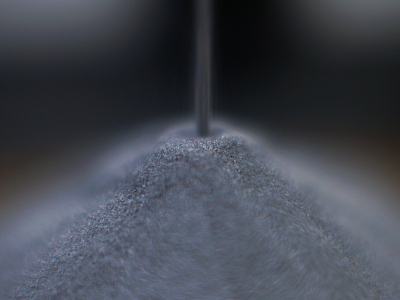

Cobalt powders for 3D printing and surface coating

Cobalt powders are commonly used to manufacture superalloys which ar used to produce magnetic, wear- and corrosion resistant and high-strength products. Alloys based on cobalt powders are suitable for applications such as blades in jets and gas turbines where its temperature stability is important. Alloys where cobalt powders are combined with chromium and molybdenum are used for prosthetic parts such as knee and hip replacements and in dental applications. Like iron, cobalt is magnetic and can be used to make magnets.

Cobalt powders are mainly used in key technologies such as additive manufacturing (AM) and surface coating. Höganäs’ AM-specific cobalt powders are often alloys that consist of cobalt, chrome and other metals such as molybdenum and nickel.

When it comes to surface coating applications, the powder is added to a surface, making it much harder and more resilient against wear, corrosion etc. Surface coating encompasses many different deposition techniques where the use of alloys based on cobalt powders is common, such as laser cladding and plasma transferred arc (PTA).

Find your cobalt powders at Höganäs:

Metal powders contribute to sustainable development

Metal powder technology provides endless opportunities; not only does it enable our customers to reduce their material and energy consumption, but it also helps them use new and better techniques that make final products more efficient and less expensive.

We believe that the inherent power of metal powders can be utilised to a much larger extent than it is today. We are also convinced that metal powders can contribute to sustainable development. With metal powder solutions, we can contribute to solving many of society’s pressing challenges, such as resource scarcity and the need for renewable energy.