Customised AM metal powders

Höganäs is at the forefront of metal powder technology for additive manufacturing and offers the broadest range of products and production techniques available in this highly specialised industry area. Our unique metal powder forAM® is already being used for the 3D printing of implants and surgical tools in the medical and dental industries, and for intricate components in the aerospace sector.

But that is just the beginning. We are developing a wide range of customer-specific metal powders that explore the limits of powder production and design, working in close collaboration with our ground-breaking additive manufacturing partners. In this highly technical field, we have the know-how and experience to develop the right metal powder technology for you, whatever your future 3D printing requirements may be.

Tailored high quality materials in scalable quantities

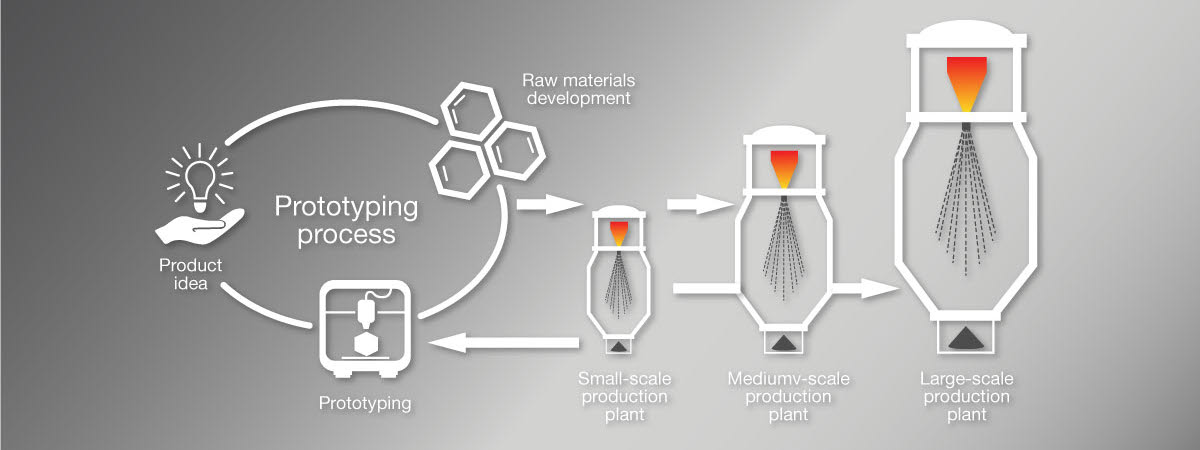

Efficiency means moving product innovations directly from lab to industrial scale. That’s where Höganäs comes in and creates customer-specific metal powders for you.

Customer-specific powder development

Particle size distribution, morphology and chemical composition are unique. Just like your product ideas. For your new market opportunities, we develop the powder you need.

Easy upscaling of production volumes

We have powder production with different capacities all around the world. Our small-scale production plant is the first choice for research and development purposes, whereas our mid- and large-scale atomisers are ideal for medium or industrial scale production. Consequently, we can simply ramp up production volumes of your customer-specific metal powder as soon as your demand increases.

Constant high quality

Our plants are identical in terms of technology, from order to order, from batch to batch, from bottle to bottle. This enables consistently high-quality standards, identical morphology and consistent particle size distributions in combination with fully optimised production processes. To put it simply: We can produce any quantity of your customised powders, from lab to medium or industrial scale production.

Market readiness on demand

When you have a highly demanded product, avoiding bottlenecks is essential in production. With Höganäs, upscaling is easy. Once we have developed and aligned the chemical and physical properties of our customer-specific metal powder perfectly to your requirements, we simply ramp up production. No lengthy upscaling processes. No waiting time. Just start your series production right away!

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

Production processes

Plasma atomising

In Luleå, Sweden, you find our ground-breaking production unit where we are developing a new standard for spherical metal powders for 3D printing. Our production process is pioneering and we are working on optimising it for industrial scale.

Benefits of plasma atomised metal powder include:

- Full density, clean, highly spherical particles without satellites

- Widest selection of materials including metals, alloys, carbides, borides, inter-metallics and more

- Tailored particle microstructure

- Great potential for most demanding applications including aerospace, medical and oil & energy

- An innovative atomisation process that explores the limits in powder design and production

- Trial materials that can be supplied for selected projects

Nitrogen atomised powders

Höganäs has a long history of producing unique metal powders in large volumes for many demanding applications – not only for the manufacture of automotive parts, where both quality and cost requirements are known to be crucial, but also for other high-end manufacturing industries. Our nitrogen atomised powders:

- Offer consistent properties with excellent flowability

- Are highly spherical with high packing density

- Are suitable for large scale manufacturing lines

Vacuum melting – inert gas atomisation (VIGA)

In our vacuum inert gas atomisation process, we can produce any quantity of customer-specific metal powder, from lab scale up to medium or industrial scale production to support you through the various stages of your product development.

Our high-quality cobalt-, nickel- and iron-based forAM® metal powders fall under this category and have been designed specifically for the requirements of additive manufacturing.

Water atomised powders

This cost-effective production technique is currently used to produce low-alloy iron and steel powders for pressing and sintering. But it also has great potential for additive manufacturing. Höganäs is driving this development, testing powders that could provide a more cost-efficient alternative for 3D printing.