Deposition techniques

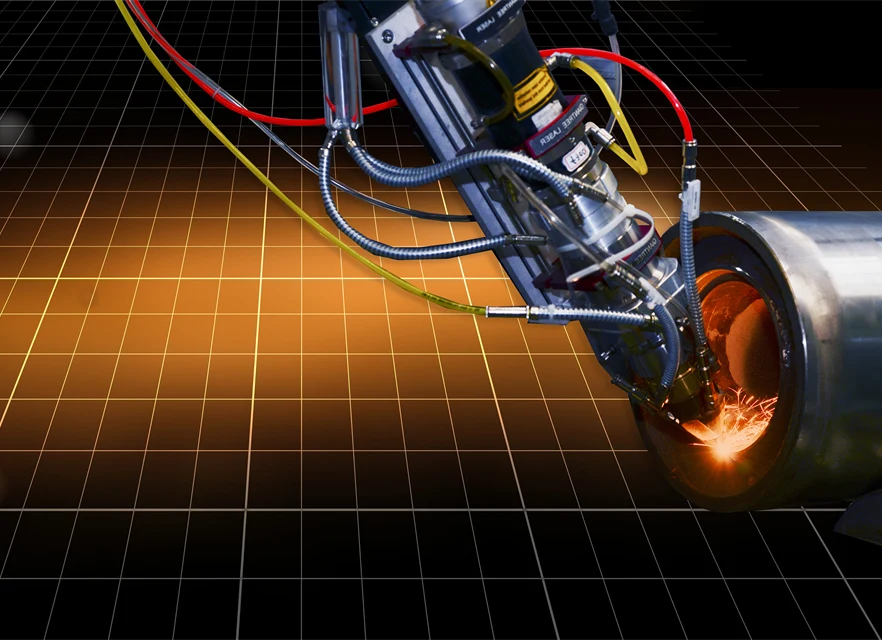

Efficient deposition with cold spraying

With cold spraying, metal powders are sprayed with a supersonic compressed gas jet (nitrogen or helium) at very high velocity and at temperatures below their melting point. The impact binds the particles onto the surface and thick layers of deposited material can be built up rapidly. The deposition efficiency is very high, above 90 percent in some cases.

Cold spraying can be used to deposit a range of metals, including copper, aluminium, bronze, super alloys and steel.

The cold spraying technique is used to repair worn-out components. It is also used to provide protection against corrosion and abrasion or to improve properties such as thermal and electrical conductivity. The process is common in the aerospace, automotive, energy, military, electronics and medical industries.

Some of the advantages of cold spraying include high density and hardness of coatings, high thermal and electrical conductivity of coatings and low energy consumption. Other benefits include the possibility to spray very small particles, no toxic waste and a minimum of preparation.

Cold spraying technology can also be utilised in additive manufacturing to develop parts faster than other additive manufacturing methods.

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

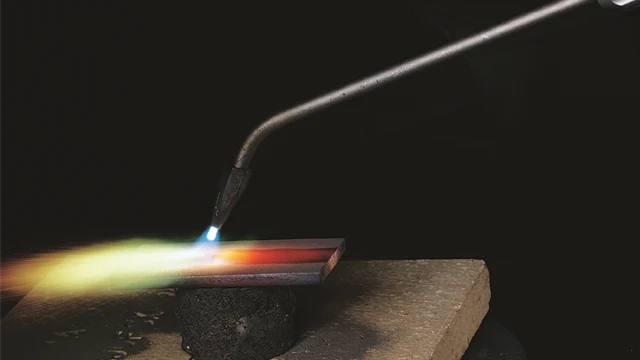

ArcX coating hub

ArcX – Your starting point for innovation

Expert know-how in materials, surface welding and flame spraying processes and customer applications make our ArcX technology centres an exclusive resource in your work to optimise existing applications and develop new business opportunities.