Environmental

Environmental impact

Future proofing the business means meeting the requirements of our future society everyday by ensuring high quality products, operational excellence and safety, while at the same time meeting higher demands concerning environmental performance and resource efficiency. Our ambitions are clear: the highest quality in all we do. An operational focus on quality reduces loss of material and energy, and reduces interruptions that can lead to failure of machines and equipment.

Agreed and documented ways of working form the basis of continuous improvement and knowledge sharing. No matter how rigorous the routines and regulations, quality can always be improved and we constantly work to meet and surpass expectations.

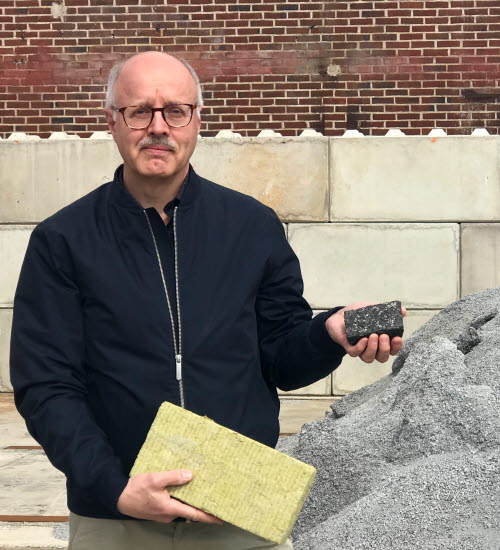

Björn Haase, who works with side-streams shows insulation and asphalt made from slag.

Turning side steams into products

All our by-products have the potential to be reused and transformed into products. Part of our side-stream materials, such as classified fractions of slag, can be directly recycled as raw materials or as consumables in our own production.

We have developed a range of products from side-stream materials, such as fillers in asphalt, construction materials and raw material for the production of stone wool, just to mention a few. Two of our most useful product developments are Petrit® E and Petrit® T, which are both made out of slag. Petrit E can be used to replace gravel in road construction and Petrit T functions as a lime replacement

We are also currently exploring the possibility of using mineral-based by-products as filter media for water treatment purposes, and to produce lime additive products used in agriculture, which improves the quality of the soil for agriculture.

Responsible use of water

The largest quantity of water used is sea water for cooling in closed systems. The heat produced in these systems is exported as district heating in Sweden.

Water is also used in the atomizing process, where molten steel is atomized into the desired particle sizes. The water is treated, cooled and largely recycled in the atomizing process again. Some water is lost in the cooling towers as vapour, and a small amount is also exchanged in order to maintain water quality, rendering an average of about 90–96 per cent recirculation grade in these systems.

We monitor our water discharges and measure substances of concern. Terms for water discharges are part of our environmental permit at most operational sites.

Emissions to air

Our production processes generate air emissions both via stack and as fugitive emissions. To prevent fugitive emissions, all raw materials and products (metal powders) are handled in closed processes, including in in-house storages and sealed transport containers of materials, with a few exceptions. The site in Höganäs, Sweden, uses bulk transport by ship and the unloading is open. Special procedures – including watering, road sweeping, landfill covers – are used to minimize emissions from open handling. A combination of paved roads and working areas, and a programme for keeping the sites clean at all times, minimizes secondary dust emissions.

To minimize stack emissions, all large point sources are equipped with filters. Local environmental control programmes typically include monitoring emissions such as nitric oxides (NOx), and sulphur oxides (SOx), metals to air, and other substances of concern, depending on the nature of the process.

Use of material

We handle about 700,000 tonnes of direct materials. Our largest raw materials are non-renewable in the sense that they are extracted from the earth’s crust. These materials are mainly iron ore, limestone and fossil process coal or coke. An initiative is ongoing to replace fossil process coal with renewable alternatives.

Metals can be recycled innumerous times, and approximately 50 per cent of our raw materials base consists of secondary, or recycled materials. Our largest material type by weight is iron-based scrap. Secondary materials include both industrial and end consumer scrap (pre- and post-consumer scrap).