Are you looking for the perfect surface coating solution that fits your needs?

A metal object can be surface coated on the exposed area to achieve high wear, corrosion resistance or thermal insulation. Surface coating can also be used to repair damaged parts. Complete part replacement is then unnecessary and this refurbishment effectively extends the lifetime of the part.

The common denominator for all of these applications is the need to achieve wear, corrosion, heat, abrasion and/or impact resistance. This combination of properties needs a dedicated surface coating powder formulation for the specific application.

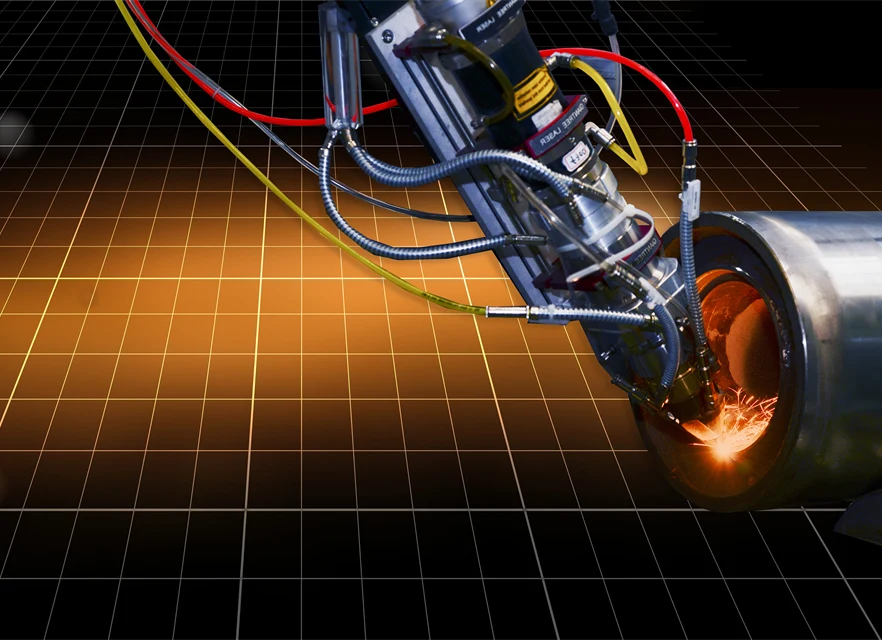

Our powders are particularly suited to the needs of surface coating processes and applications such as powder welding, flame spraying, plasma spraying, HVOF (high

velocity oxy-fuel), HVAF (high velocity air-fuel), PTA (plasma transferred arc), laser cladding and cold spraying.

Coatings are today standard practice for many applications in a wide range of industries:

|

|

Surface coating deposition techniques

Our brands stand for high quality and reliability in the global surface coating market

Our business is defined by our customer focus and customer partnerships, which have made us one of the most successful spray powder manufacturers in the world. Working with original equipmet manufacturers (OEM) is our tradition.

In order to meet customers' needs in coating processes, we pay particular attention to specific requirements of controlled chemistries, precisely defined grain forms and morphologies, as well as adjusted particle size distributions.

Over the past few decades. we have acquired the necessary knowledge of how to develop new materials and recycling processes, and how to improve the products we provide to our customers.

Rockit® 606/706 powders are designed to improve the performance of components operating in the toughest environments where impact and severe abrasive wear occur.

Find out more about abrasive wear with Rockit here.

Comprehensive application engineering offers a unique advantage for Amperit® powders, ranging from parameter development to complete coating solutions.

Under the brand name Amperweld®, Höganäs is a quality supplier of metals and alloy powders for surface welding.

Each of our Amperweld powders is designed for a specific welding process with tightly controlled particle size distribution and morphology.

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.

Highlights

The range of surface coating equipment techniques and powders in use has grown in pace with the growth of the surface coating industry.

We produce a full range of nickel-, iron- and cobalt-based atomised powders for all kind of applications and industry areas. Get inspired among some of our highlights.

ArcX coating hub

ArcX – Your starting point for innovation

Expert know-how in materials, surface welding and flame spraying processes and customer applications make our ArcX technology centres an exclusive resource in your work to optimise existing applications and develop new business opportunities.

Metal powders contribute to sustainable development

Metal powder technology provides endless opportunities; not only does it enable our customers to reduce their material and energy consumption, but it also helps them use new and better techniques that make final products more efficient and less expensive.

We believe that the inherent power of metal powders can be utilised to a much larger extent than it is today. We are also convinced that metal powders can contribute to sustainable development. With metal powder solutions, we can contribute to solving many of society’s pressing challenges, such as resource scarcity and the need for renewable energy.