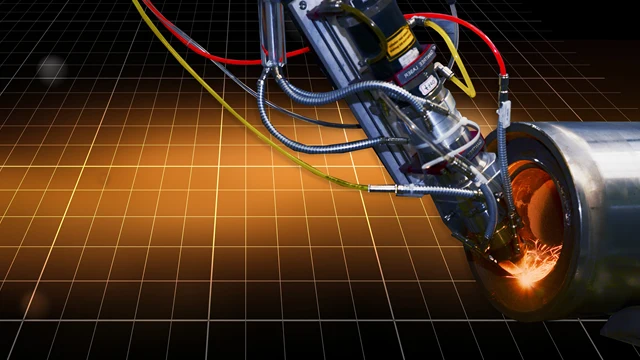

Cobalt-based powders for plasma transferred arc (PTA)

Surfit® cobalt (Co) based powders

Surfit 2528-00 | Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2728-00 | Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo | 212/63 µm

Particle size: 212/63 µm

Chemistry: Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo

Powder type: Gas atomised

Typical deposition techniques: Plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2537-00 | Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2737-00 | Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W | 212/63 µm

Particle size: 212/63 µm

Chemistry: Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W

Powder type: Gas atomised

Typical deposition techniques: Plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2537-10 | Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2737-10 | Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W | 212/63 µm

Particle size: 212/63 µm

Chemistry: Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W

Powder type: Gas atomised

Typical deposition techniques: Plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2540-00 | Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2740-00 | Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W | 212/63 µm

Particle size: 212/63 µm

Chemistry: Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W

Powder type: Gas atomised

Typical deposition techniques: Plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2541-00 | Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2741-00 | Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W | 212/63 µm

Particle size: 212/63 µm

Chemistry: Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W

Powder type: Gas atomised

Typical deposition techniques: Plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2541-10 | Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2741-10 | Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W | 212/63 µm

Particle size: 212/63 µm

Chemistry: Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2548-00 | Co 2.3C 1.2Si 30Cr 1Fe 13W | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co 2.3C 1.2Si 30Cr 1Fe 13W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit ST 156 | Co 1.6C 1.1Si 27.5Cr 1.8Ni <1Mo 4W | 150/45 µm

Particle size: 150/45 µm

Chemistry: Co 1.6C 1.1Si 27.5Cr 1.8Ni <1Mo 4W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit HB 400 | Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo | 150/53µm

Particle size: 150/53 µm

Chemistry: Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit HB 400 | Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo | 150/63µm

Particle size: 150/63 µm

Chemistry: Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit HGMET LFE | Co <0.1C 0.3Si 0.7Fe 27Cr 9.5Ni 5Mo 0.8Mn 2W | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co <0.1C 0.3Si 0.7Fe 27Cr 9.5Ni 5Mo 0.8Mn 2W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit HB 800 | Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo | 150/53 µm

Particle size: 150/53 µm

Chemistry: Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo

Powder type: Gas atomised

Typical deposition techniques: Plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit HB 800 | Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo | 210/63 µm

Particle size: 210/63 µm

Chemistry: Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo

Powder type: Gas atomised

Typical deposition techniques: Plasma transferred arc (PTA)

|

Remarks:

|

||

Surfit 2748-00 | Co 2.3C 1.2Si 30Cr 1Fe 13W | 212/63 µm

Particle size: 212/63 µm

Chemistry: Co 2.3C 1.2Si 30Cr 1Fe 13W

Powder type: Gas atomised

Typical deposition techniques: Laser cladding, plasma transferred arc (PTA)

|

Remarks:

|

||

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.