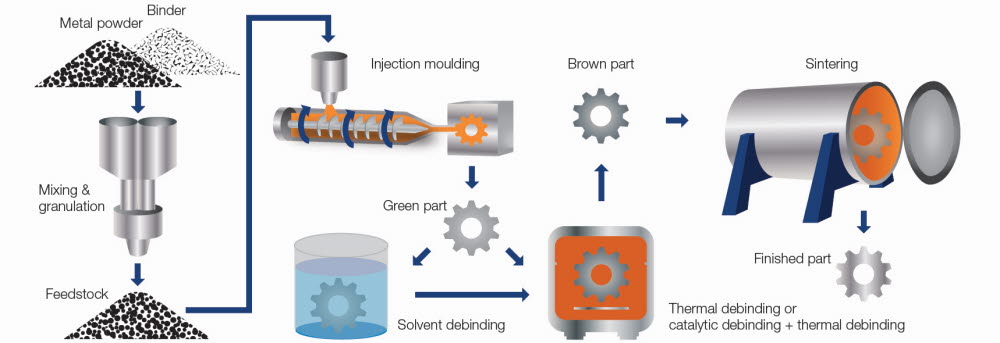

The metal injection moulding process

This is how the metal injection moulding (MIM) process works

In the MIM process, metal powders and a binder system are combined to produce the feedstock. The binders can consist of polymers such as wax and polypropylene.

The feedstock is moulded into a “green part,” cooled and ejected from the mould.

In the next phase of the metal injection moulding process, the binder material is removed while the part is sintered to a solid shape. Sintering heats the powder to temperatures near the melting point to densify the particles. Diffusion rates are high, which lead to high shrinkage and densification.

The cost benefits of metal injection moulding applications lie in complexity of geometries in combination with high volumes of small-size parts (typically less than 50 mm).

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.