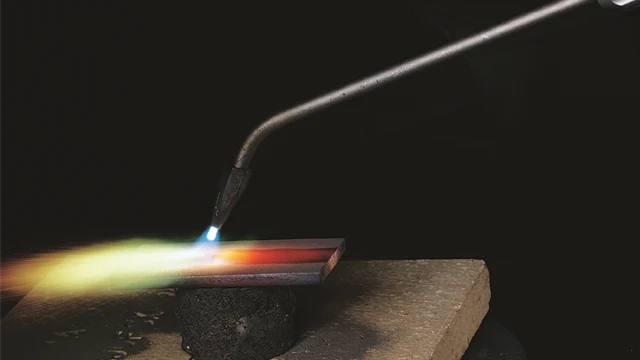

Deposition techniques

Powder welding troubleshooting

Problems with your powder welding process?

| Problem | Cause | Solution |

| Deposit peels off | 1. Poor preparation of the surface (oxidized or dirty surface) 2. Required surface roughness is >Ra 5 3. Too low preheating temperature 4. Too high preheating temperature 5. Too high content of S & Ti in the cast iron base |

Clean the surface well |

| Cracks |

1. Overheating |

Slower cooling / controlled cooling |

| Porosity |

1. Poor preparation of the surface |

Clean the surface well |

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.