3D printing – A driving force in automotive innovation

3D printing in automotive industry – believe the hype

Recently, the automotive industry is making great strides in the integration of metal additive manufacturing technologies, 3D-printing. Great opportunities arise especially within the performance autosports and heavy commercial vehicle segment. Here, the innovative process is increasingly growing common for functional prototypes and low volume spare part manufacturing.

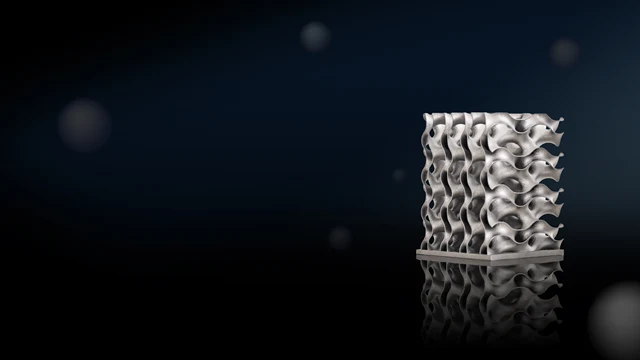

With our very high level of material expertise and our comprehensive portfolio of high quality metals for additive manufacturing, we support you in achieving optimum product properties with additive manufacturing. Our sophisticated steel powders for instance are the first choice for prototyping and tooling applications.

Tooling – the heart and soul of perfect 3D printed parts

Tooling consists of instruments or components typically used for creating geometrical shapes in various production processes. Those production processes include injection moulding, casting, cutting, stamping, extrusion and assembly. Typical categories of machine tooling include fixtures, jigs, gauges, moulds, dies, cutting equipment and patterns. It is common that tooling components are produced in comparatively low volumes, which is driving up costs.

Using tools with the right material and quality is critical for manufacturers. Additive manufacturing offers possibilities to introduce internal cooling channels into moulding tools or optimize coolant supply for cutting tools. This opens wide opportunities for reduction of manufacturing costs and productivity improvements.

The process of making tools is time-consuming and expensive. Intricate geometries, high precision and surface finish requirements combined with hard and wear resistant materials apply extremely high demands of a highly qualified workforce and equipment. In-house metal 3D printing enables a faster and cheaper way to produce tooling. Metal 3D printing your tooling means that you can act faster, increase productivity and improve functionality of your tooling. Being able to drastically reduce delivery time is a big advantage.

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.