Brazing

joining innovations

Corrosion

Corrosion resistance is one of the most important properties for brazing alloys. Normally testing is done in service on finished components, but Höganäs have made an effort to be able to give a statement on corrosion resistance of different the different BrazeLet® alloys.

Höganäs has designed various different tests in order to understand how certain corrosive environments affect the brazing joints, to better be able to recommend suitable alloys for specific applications.

In the general case, when evaluating corrosion, it is important to understand that there are three major parts that need to be evaluated:

- Base material corrosion

- Brazing filler metal corrosion

- Diffusion zone corrosion

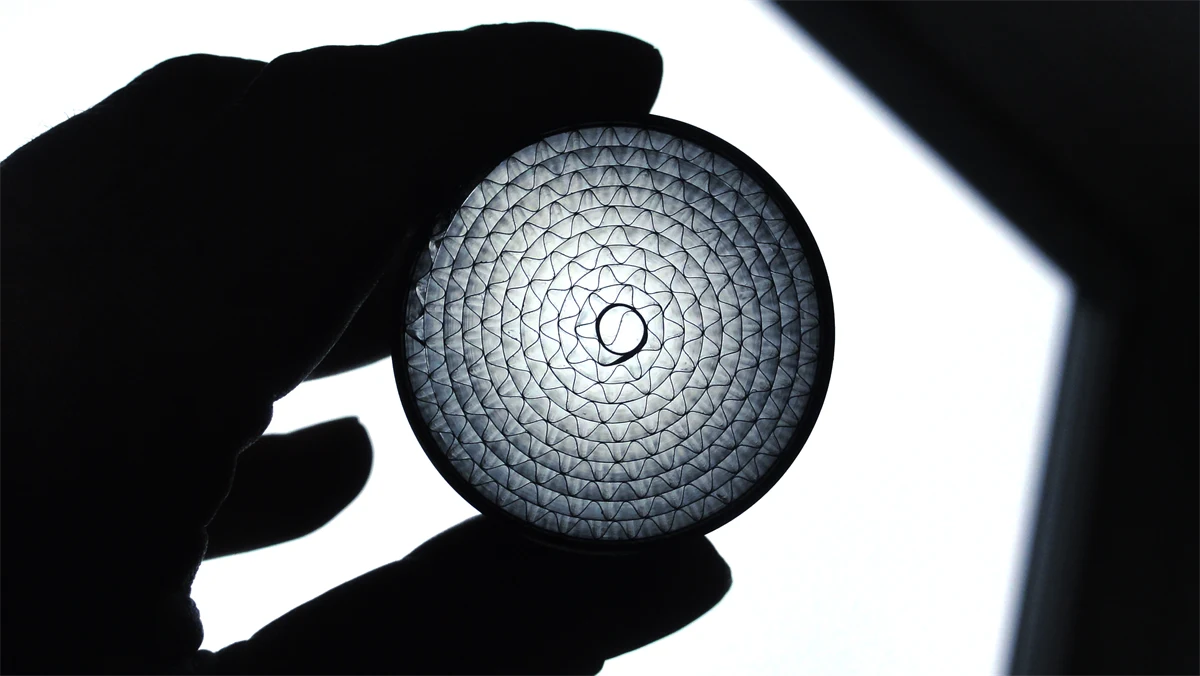

Höganäs internal corrosion resistance evaluations are all based on SS316L as base material. The corrosion resistance is evaluated both qualitatively (microscopic evaluation after testing) and quantitatively (high-precision weight measurements with set time intervals during testing). The results from both evaluations are concluded into a recommendation for different BrazeLet filler metals in combination with different corrosive media.

- Inter-phaseiary corrosion of certain phases in the microstructure (low Cr or Cr tied to something else than O).

- Intergranular corrosion of boron-infiltrated diffusion zone

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.