Brazing – joining innovations

Pastes and filler metals

Complete solutions for your high temperature brazing needs

Definition of Brazing

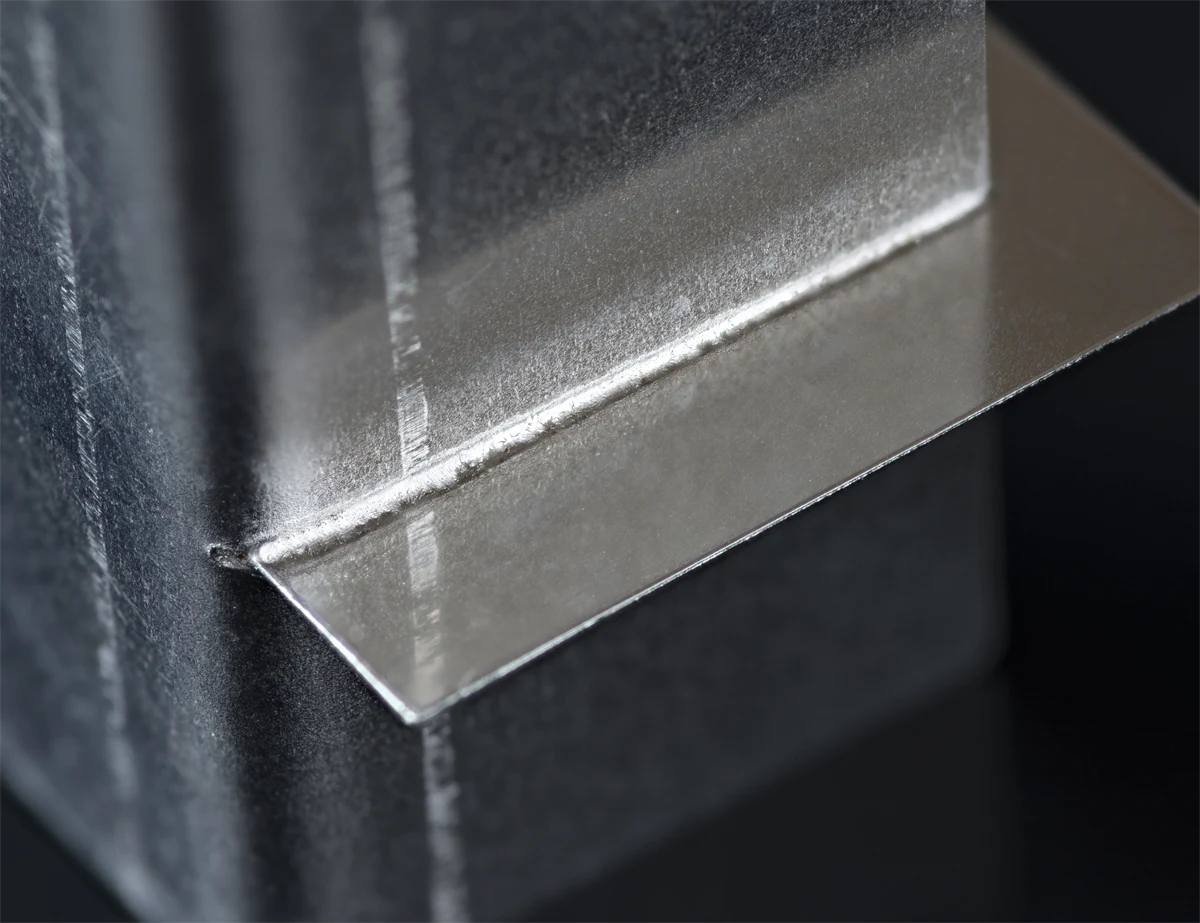

Brazing is a thermal process for securely joining materials. The parts are heated up to the working temperature of the brazing alloy which flows into the gap by capillary action. One big advantage of brazing is that virtually any metallic materials can be combined. A prerequisite for brazing is the spreading of the molten alloy (wetting) on the base material.

Why Brazing?

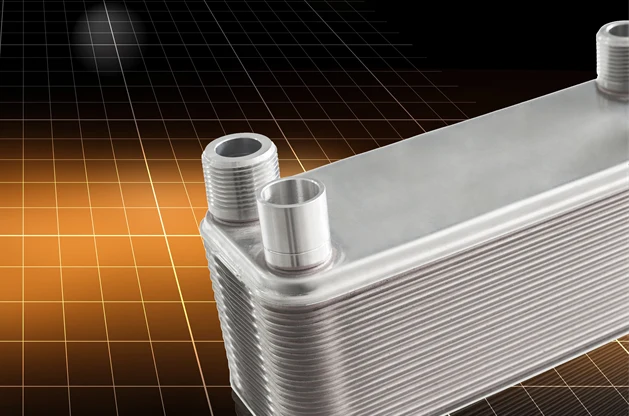

One example where brazing is superior to other techniques is for manufacturing heat exchangers resistant to corrosion and high temperatures. The core component designs often does not allow the parts to be joined by welding. Even if it is possible, welding is a serial process where production time is proportional to total joint length, whereas brazing of hundreds of heat exchangers can be done in one batch simultaneously.

Why Höganäs brazing?

Höganäs offer stainless steel filler metals for reliable braze joints fulfilling customers demand in properties, lifetime and quality of their components. As the global leader in metal powders, Höganäs has in-depth knowledge about high-temperature brazing filler metals and how to fine-tune their properties. Development of new filler metals by R&D benefit by pilot center for atomizing small batches of powder, metallographic and analytic labs and our Customer Development Centre for testing applications, all located in Höganäs Headquarter, Sweden.

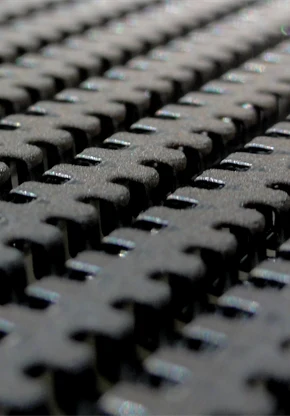

For application of the brazing filler metal the powder is offered as unique pastes. Höganäs brazing pastes have fine-tuned properties shaped for reliable and sustainable selective application methods like dispensing, roller coating or screen printing. The Höganäs Brazing filler metal powder and paste production is located in Ath, Belgium. Production is certified according ISO9001, ISO14001 and IATF16949 following automotive standards.

Learn more

Customer-specific development and support

Höganäs' Customer Development Centre provides all necessary prerequisites for working with material development, application design and prototyping, as well as process optimisation under one roof. Here we have the capacity to work together with customers and end-users at every step from testing to prototyping of brazing applications to evaluate the best solution.

Our services:

- Application development

- Filler metal application

- Paste application

- Brazing process

- Continuous improvements

Application-driven innovation

The starting point is always your specific application needs. As our customer, you will work in close co-operation with us at every stage, from analysing all aspects of the application requirements, to the suggestion of an optimum solution with the desired properties.

As the global leader in metal powders, we have acquired in-depth knowledge about high-temperature brazing filler metals and how to fine-tune their properties. Moreover, we have the capacity and application knowledge required to turning brazing filler metals into optimum brazing paste solutions.

We want to make sure that your brazing solution consistently generates good results. For that reason we have established a global technical support network providing in-house as well as on site services.

This means that our involvement does not end with delivery and that you can expect customer support every step of the way.

Why choose Höganäs?

With a partnership approach and unrivalled expertise, we are in a unique position to deliver cutting-edge solutions that cost-effectively match your application requirements. In Höganäs you will find a partner highly active in R&D, creating an ideal environment for joint development of new filler metals to meet changing market demands.

Contact us

Sales & Technical support

Privacy policy

I agree that Höganäs can handle my personal data in order to contact me. My contact information may also be used in marketing purpose, such as newsletters and other relevant information. The data will not be shared with a third party. With my consent, I also confirm that I am over 16 year old.

More information about how we handle personal data can be found in our privacy policy.