Products

Sustainable offering

For example, by using powder metallurgy, complex parts that are close to net-shape and with good part-to-part uniformity, can efficiently be mass-produced with fewer production steps. This leads to high material utilization, low energy consumption and reduced waste.

Metal powders, such as soft magnetic composites (SMC), can maximise the utilisation of active materials in electromagnetic applications. And surface coatings made from powdered metals can improve a component’s wear and corrosion resistance, and thus increase its lifetime in a sustainable way. We can offer metal powder-based solutions for drinking water purification that can improve the lives of millions of people worldwide.

Additive manufacturing, while still under development, offers huge potential for improving resource efficiency and extending product life.

However, sustainable development is not something we can achieve alone – we need to work with others. Höganäs has a long tradition of working on projects with our customers, universities, research institutes, and other industry partners. This is a tradition that we are continuing as we tackle the industry’s sustainability challenges.

Life-cycle assessments

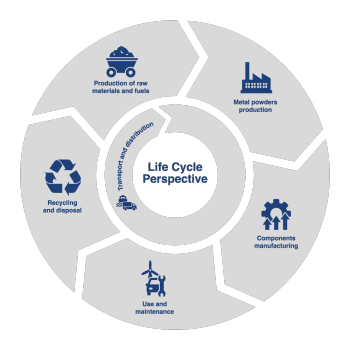

All stages of a product’s life cycle must be considered for sustainable industrial development. Quantification of the product footprint can give useful input for qualified decisions on changes and improvements in production or supply, as well as new product developments. We therefore run two initiatives with the goal of mapping metal powders’ environmental performance.

Internally, we have begun a systematic approach with life cycle assessments (LCA) focusing on cradle-to-gate analysis covering the parts of our products’ life cycle that we can directly influence. Moreover, we have started an industry-wide initiative on life cycle assessments within the European Powder Metallurgy Association (EPMA), starting with a lighthouse project to quantify the complete life cycle impact of a specific powder metal part.

Stone wool is one example of a product made from side stream material.

By-products get a second life

A more obvious aspect of closed material loops is to repurpose sidestream materials. In most of our manufacturing processes for metal powders, different kinds of by-products are generated. Depending on the properties of these materials, they can be used in various applications, often unrelated to how our main products are employed. The bulk of our side-stream products are processed from different slags. Examples of new uses for these materials include construction materials in roads or as raw materials for the manufacturing of stone wool (insulation material). Other side-streams include zinc recovery from melting furnace dust and recovery of iron from other dusts.

At the Ocean Conference in 2017, held at the UN headquarters in New York, Höganäs signed a voluntary commitment on the use of by-products from the steel industry for water purification. We are now engaged in a research project partnership in Sweden (Minrent) to explore the possibilities of purifying water of phosphorus by using tailored filter materials made from slags.

We regularly participate in cooperation projects on side-stream products, such as the recently finished project ‘Slagphalt’, which was a cooperation between the steel industry, asphalt industry, research institutes and authorities. The project has shown some major benefits with slag asphalt, such as higher shear strength (important in roundabouts for example), higher friction and significant noise reduction. These results have created a higher demand for slag asphalt and opened up new areas of usage for steel slag.

Read more how Höganäs uses side streams:

Sustainable development needs partnerships

In general, we believe that sustainable development needs partnerships and knowledge sharing. Höganäs has a long tradition of working on projects with our customers, universities, research institutes, and other industry partners. The projects’ scopes often include both our and our customers’ technology areas at all technical readiness levels. In most cases, projects are funded by government authorities, with Höganäs as a co-funding partner, together with other companies with similar interests. In addition to these projects, Höganäs is also active in several centres of excellence and competence, focusing on, for example, materials science and raw materials.

Case stories

“We believe that sustainable offerings are a prerequisite for long-term profitability.”

Catharina Nordeman,

Director Group Sustainability

Products