Pós à base de cobalto para plasma com arco transferido (PTA)

Pós Surfit® à base de cobalto (Co)

Surfit 2528-00 | Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo

Tipo de pó: Atomizado a gás

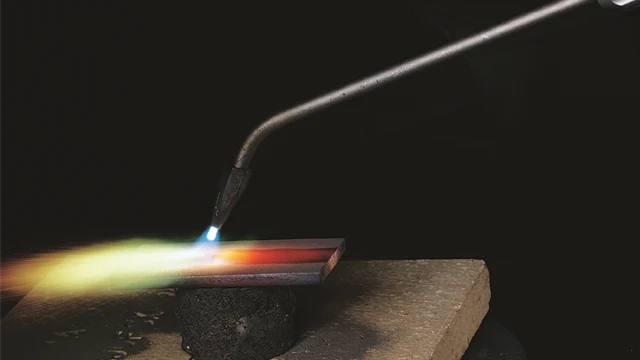

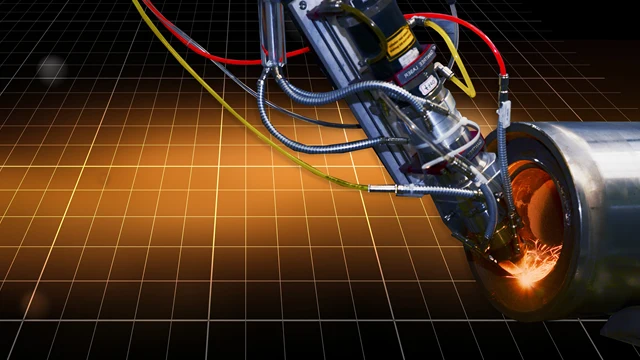

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2728-00 | Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo | 212/63 µm

Tamanho da partícula: 212/63 µm

Química: Co 0.25C 0.9Si 0.5Fe 27Cr 2.5Ni 0.7Mn 5.5Mo

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2537-00 | Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2737-00 | Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W | 212/63 µm

Tamanho da partícula: 212/63 µm

Química: Co 1.2C 1Si 1.5Fe 28.5Cr 1.5Ni 4.6W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2537-10 | Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2737-10 | Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W | 212/63 µm

Tamanho da partícula: 212/63 µm

Química: Co 1.3C 1Si 1.5Fe 28.5Cr 0.4Mn 1.5Ni 4.2W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2540-00 | Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2740-00 | Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W | 212/63 µm

Tamanho da partícula: 212/63 µm

Química: Co 1.7C 1.1Si 1.1Fe 26Cr 22.5Ni 12W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2541-00 | Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2741-00 | Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W | 212/63 µm

Tamanho da partícula: 212/63 µm

Química: Co 1.4C 1.2Si 0.7Fe 28.5Cr <2Ni 8W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2541-10 | Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2741-10 | Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W | 212/63 µm

Tamanho da partícula: 212/63 µm

Química: Co 1.85C 1.5Si <1.5Fe 30.5Cr <1Ni 8.5W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2548-00 | Co 2.3C 1.2Si 30Cr 1Fe 13W | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co 2.3C 1.2Si 30Cr 1Fe 13W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit ST 156 | Co 1.6C 1.1Si 27.5Cr 1.8Ni <1Mo 4W | 150/45 µm

Tamanho da partícula: 150/45 µm

Química: Co 1.6C 1.1Si 27.5Cr 1.8Ni <1Mo 4W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit HB 400 | Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo | 150/53µm

Tamanho da partícula: 150/53 µm

Química: Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit HB 400 | Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo | 150/63µm

Tamanho da partícula: 150/63 µm

Química: Co <0.05C 2.8Si 0.8Fe 9.7Cr 0.8Ni 29.5Mo

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit HGMET LFE | Co <0.1C 0.3Si 0.7Fe 27Cr 9.5Ni 5Mo 0.8Mn 2W | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co <0.1C 0.3Si 0.7Fe 27Cr 9.5Ni 5Mo 0.8Mn 2W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit HB 800 | Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo | 150/53 µm

Tamanho da partícula: 150/53 µm

Química: Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit HB 800 | Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo | 210/63 µm

Tamanho da partícula: 210/63 µm

Química: Co <0.08C 3.4Si <1.5Fe 18Cr <1.5Ni 29Mo

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Plasma com arco transferido (PTA)

|

Observações:

|

||

Surfit 2748-00 | Co 2.3C 1.2Si 30Cr 1Fe 13W | 212/63 µm

Tamanho da partícula: 212/63 µm

Química: Co 2.3C 1.2Si 30Cr 1Fe 13W

Tipo de pó: Atomizado a gás

Técnicas típicas de deposição: Revestimento a laser, plasma com arco transferido (PTA)

|

Observações:

|

||

Fale conosco

Vendas e suporte

Política de privacidade

Concordo com o processamento de meus dados pessoais pela Höganäs para que possa contatar-me. Minhas informações de contato também podem ser usadas para fins de marketing, tais como envio de boletins informativos e outras informações relevantes. Os dados não serão compartilhados com terceiros. Juntamente com o meu consentimento, também confirmo que tenho mais de 16 anos.

Para saber mais sobre como processamos informações pessoais, consulte a nossa política de privacidade.