What’s sintering?

– And what are its advantages?

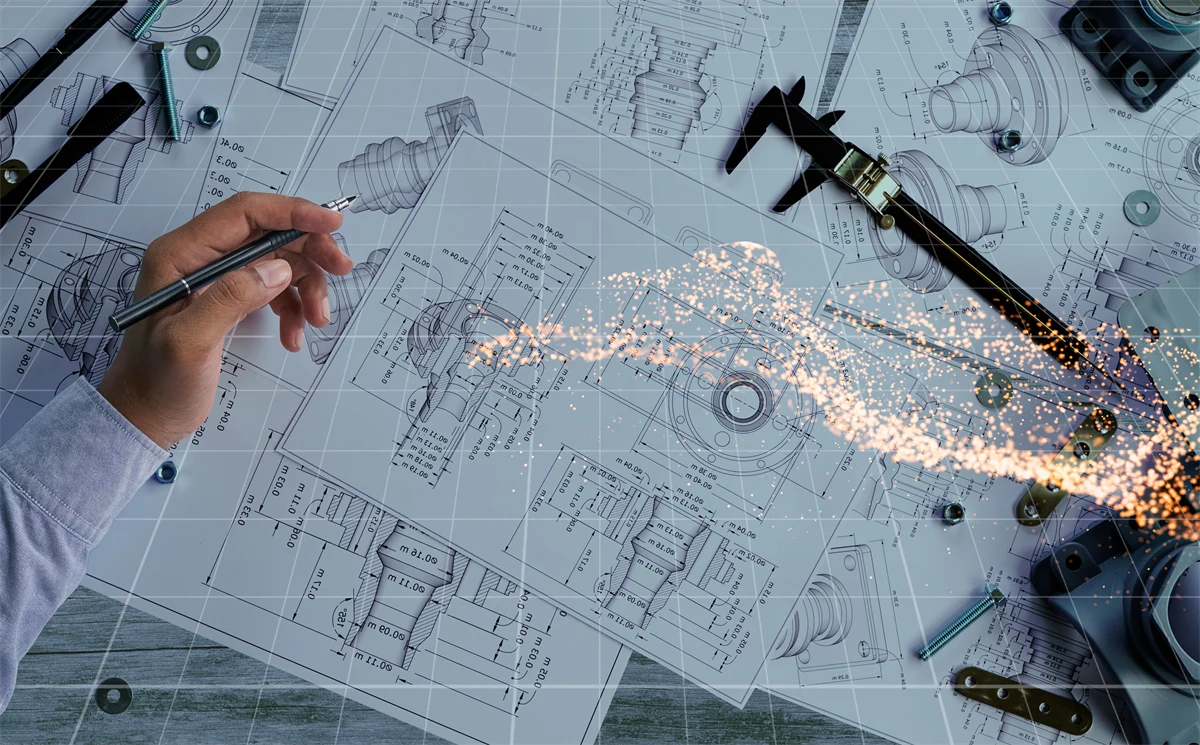

Create solid metal components through sintering

The first step in making a sintered component is the compaction process where powder is formed into a component’s net shape by a pressing tool. The punches press the powder particles together using very high forces. The powder used for sintered components can be made of metal, ceramic, plastic and other various materials. Using iron-based metal powders is very common for sintered parts.

Sintering is a process where the compacted powder particles are joined to a solid mass of material using heat while the particles are still solid. Sintering of steels is done in a controlled atmosphere at high temperatures (1,120 °C is common) but below melting point of iron (1,538 °C). Even though the particles are not molten during the heating process in the sintering furnace, they still form strong metal connections. During the sintering process, material from the powder particles transports to points and areas where they are in contact with one another. This transport of material (called diffusion) creates so called sintering necks between particles. The sintering process gives controlled porosity and enhances properties such as strength and electrical conductivity.

High performance at low cost

So, what’s sintering good for? The compaction and sintering techniques are preferably used for metal components manufactured in large quantity, i.e. series of more than 10,000 pieces. Sintered components are commonly used in the automotive industry for making gears, planetary carriers and shock absorbers, but also for power tools and domestic components. The majority of sintered components produced are small and weigh 0.1-1.0 kg. However, technical developments enable sintered components weighing several kilograms per piece. What’s sintering’s main advantage? Well, the compaction and sintering production method offers high performance at lower total cost.

隐私政策

我同意Höganäs以联系我为目的处理我的个人数据。 我的联系信息也可能用于营销,如业务通讯和其他相关信息。 数据不会与第三方进行共享。 本人已同意,并且确认已年满16周岁。

更多关于我们如何处理个人数据的信息,请参阅我们的隐私政策。

Welcome to Höganäs Academy

Join Höganäs Academy and learn more about the capabilities and opportunities for pressed and sintered metal components.

In our online courses at Höganäs Academy, you get access to everything from an easy-to-read overview of what sintered components are and how they are produced to profound process know-how on how to optimise production efficiency and quality.