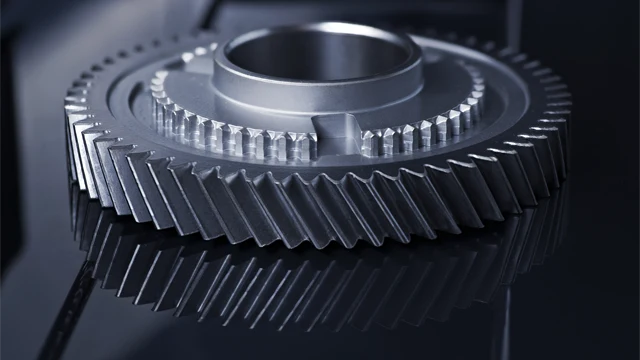

Crank- and camshaft sprockets require precise tooth profiles, high core strength and exceptional wear characteristics to allow for maintenance-free, non-slip operation.

Using powder metallurgy (PM) for manufacturing of sprockets allows for near net-shape complex geometries with reduced need for machining.

Höganäs offers material solutions that perfectly balance precision geometry with high strength and wear requirements. Ensuring better dimensional consistency and density distribution, they also feature machining enhancers that greatly reduce tool wear.

|

Benefits of Höganäs’ solution for PM crankshaft sprockets:

|

||

联系表

联系人

Technical area: 压制和烧结

选择国家/地区 *

名 *

姓 *

公司 *

电子邮件 *

工作电话 *

留言 *

隐私政策

我同意Höganäs以联系我为目的处理我的个人数据。 我的联系信息也可能用于营销,如业务通讯和其他相关信息。 数据不会与第三方进行共享。 本人已同意,并且确认已年满16周岁。

更多关于我们如何处理个人数据的信息,请参阅我们的隐私政策。

您必须先接受这些服务条款才能继续。