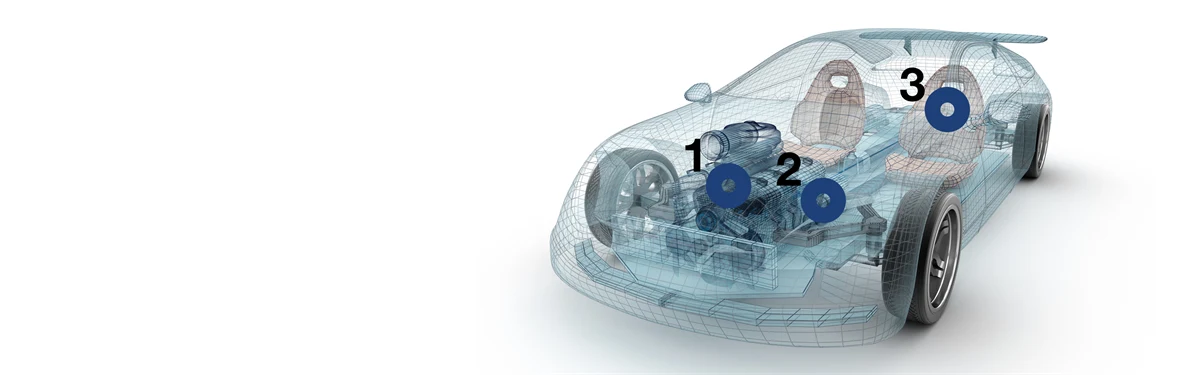

1. Internal combustion engine

2. Transmission

3. Body and chassi

Gasoline/Diesel cars

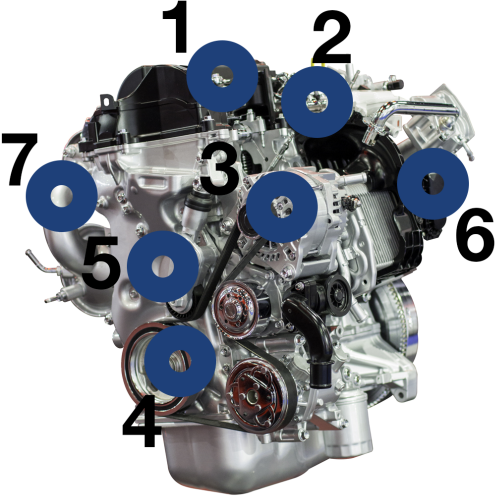

Internal combustion engine

- Fuel injection

- Ingnition systems

- Pumps

- Crankshaft

- Valventrain

- A/C compressor

- Exhaust gas reciculation (EGR) cooler

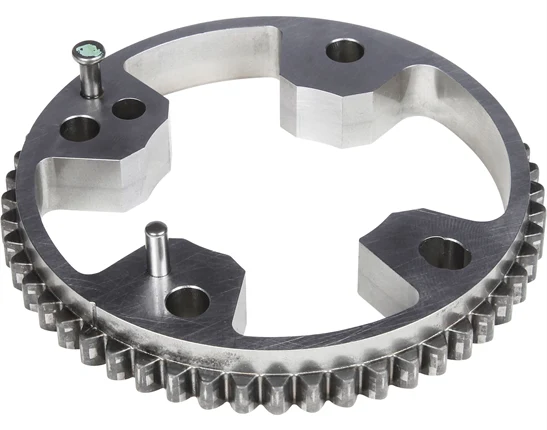

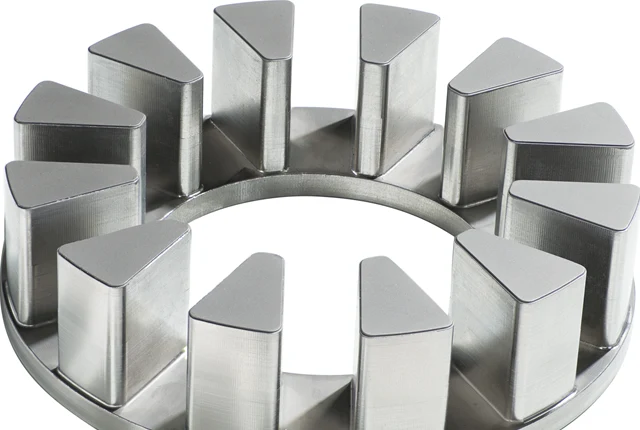

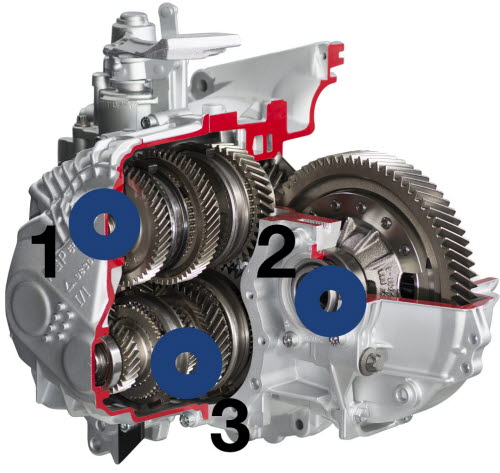

Sintered gears are crucial components in the transmission system of a hybrid engine. Transfer case sprockets, planetary carriers and differential gears are examples of suitable applications for using powder metal technology.

Sintering allows the production of complex-shaped gears with high precision, making them suitable for efficient power transmission. Another benefit with PM components is the efficient use of materials, minimising waste and reducing overall production costs. A third advantage is enhanced mechanical properties, wear resistance and durability.

Transmission

- Transfer case sprockets

- Planetary carriers

- Differential gears

The press and sinter technology is ideal for creating and producing essential metal elements in a transmission such as gears, carriers and sprockets.

The net shaping technique employed in pressing and sintering enables your company to create intricate forms through a minimal number of processing steps.

This technology offers cost benefits by eliminating the need for additional machining operations to attain the final component shape, including delicate features such as gear teeth and splines.

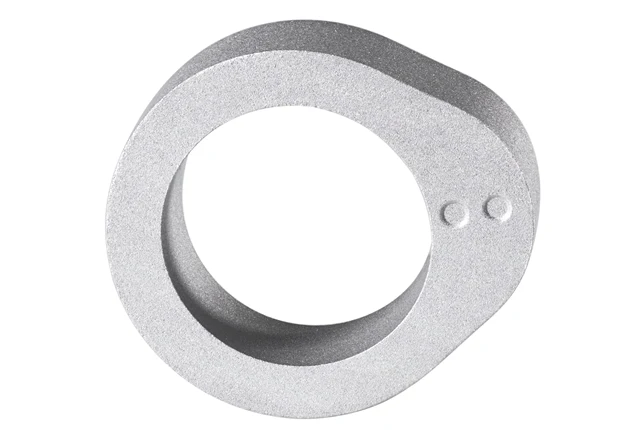

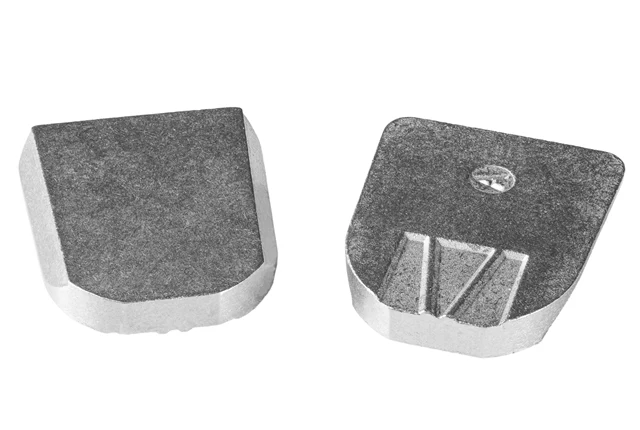

Body and chassi

- Mirrors

- Shock absorbers

The variety of applications and rigorous requirements for complex geometries, repeatability and consistency, tight tolerances and low cost drive the demand for pressed and sintered metal powder components in the automotive industry.

PM components are highly durable, wear-resistant and therefore suitable for details on the body and chassis of vehicles. Examples of parts include shock absorber pistons and rods, and mirror bosses.

隐私政策

我同意Höganäs以联系我为目的处理我的个人数据。 我的联系信息也可能用于营销,如业务通讯和其他相关信息。 数据不会与第三方进行共享。 本人已同意,并且确认已年满16周岁。

更多关于我们如何处理个人数据的信息,请参阅我们的隐私政策。